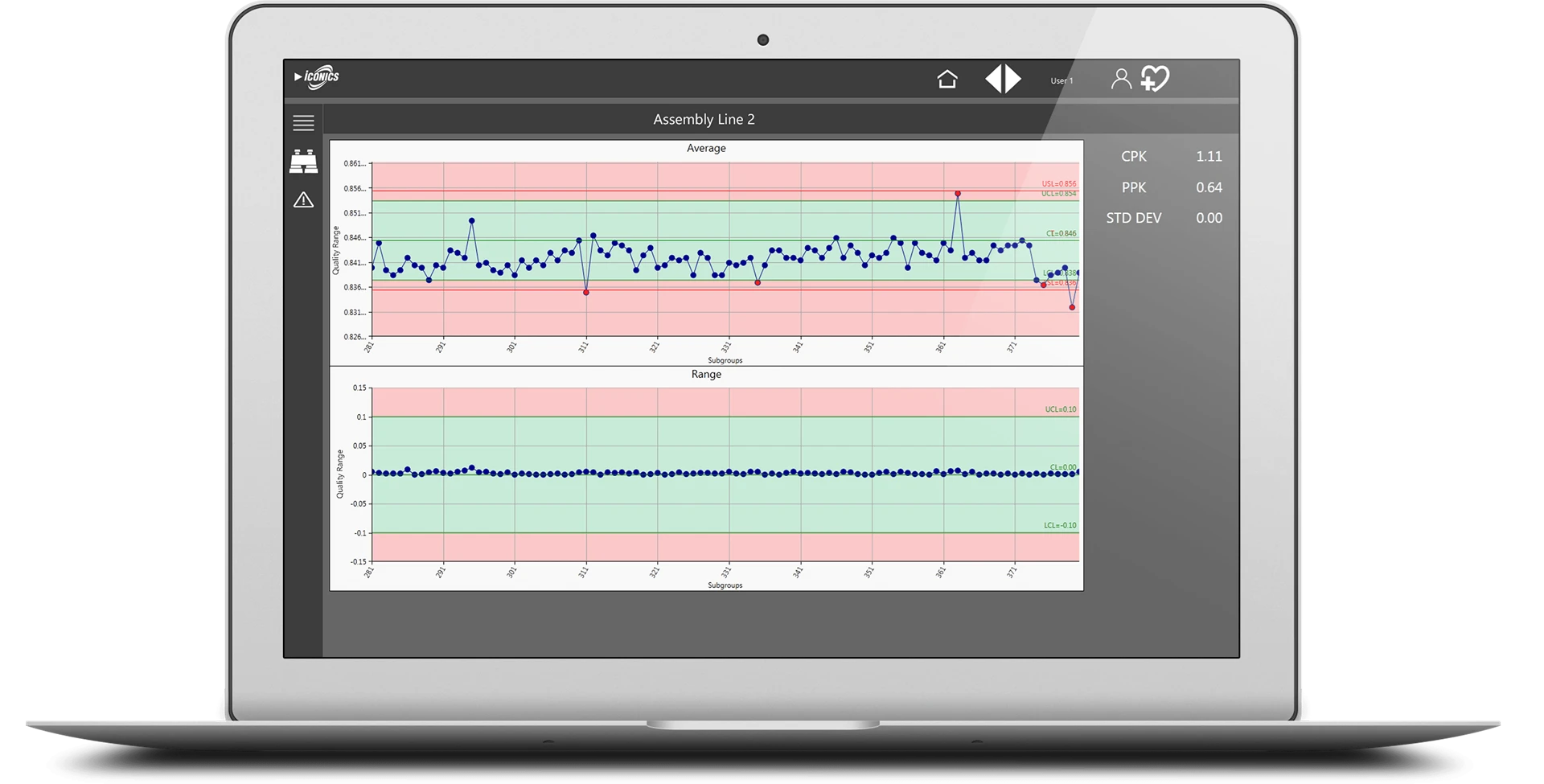

Complete SPC Quality Software Solution

Quality AnalytiX® enables operators, quality personnel, manufacturing engineers, and management to view quality SPC data and other production parameters impacting product quality. Users can apply any of the extensive set of built-in SPC calculations to any process variable and integrate SPC data into expressions and logic to drive corrective actions based on process trends. Quality AnalytiX leverages Hyper Historian™ technology for data collection and calculations. The architecture supports large enterprise-wide SPC quality programs as well as applications requiring rapid sample rates.

Ensure Product Quality

Spot trends and make decisions based on real-time SPC data with Quality AnalytiX. Reduce scrap and increase production yields using built-in charts, graphs, and alarm views. Powerful workflow technology initiates control actions based on quality conditions or alarm violations, providing changes to process equipment such as PLCs, temperature controllers, and DCS systems.

Preconfigured Calculations

Utilize preconfigured charts to calculate optimum conditions and determine saving per unit or batch. Save time by reusing calculations to optimize conditions and minimize overfills, scrap, and inefficiencies.

Product Features

Customize rule-based alarms

Combine SQC and process monitoring

Universally connect to all new and existing equipment

Unify control processes from dashboards

Utilize preconfigured calculations to optimize conditions

Minimize overfills, scrap, and inefficiencies

Want to Get Started?

Feature Download

GENESIS64™ provides the World's Most Advanced Suite of 64-bit HMI/SCADA Software Solutions.

Get in Touch

Want to get started with GENESIS? Get in touch with our Team at one of our worldwide offices.

English

English

Czech

Czech

German

German

French

French

Italian

Italian

Japanese

Japanese

Polish

Polish