Discover how automation and digital transformation are reshaping the oil and gas sector in Southeast Asia and how the GENESIS SCADA and HMI platform by Mitsubishi Electric Iconics Digital Solutions enables companies to connect, visualize, and optimize operations across the energy value chain.

Driving Digital Transformation in Southeast Asia’s Oil and Gas Industry

Industrial Digital Transformation: What Success Looks Like

Industrial digital transformation can feel uncomfortable at first—much like starting a new fitness routine—but it delivers measurable, long-term gains. This blog outlines six key components of transformation success and shows how Italian bakery Drago Forneria Genovese modernized its operations using these principles while preserving its artisanal quality.

Overcoming the Top 5 Barriers to Industrial Digital Transformation

Industrial digital transformation often stalls on legacy equipment, data silos, cybersecurity gaps, vendor lock-in, and resistance to change. This blog shares field-tested solutions to overcome these barriers and shows how GENESIS, the advanced SCADA platform from Mitsubishi Electric Iconics Digital Solutions, provides a scalable, secure foundation for sustainable modernization.

Enabling Your Company’s Industrial Transformation (IX)

Organizations can ensure a successful industrial transformation by approaching the process with a narrow focus and limited scope through several basic steps: Use the SMKL Method to assess your digitalization needs; define your value levers; and build a partner ecosystem that understands what your success looks like.

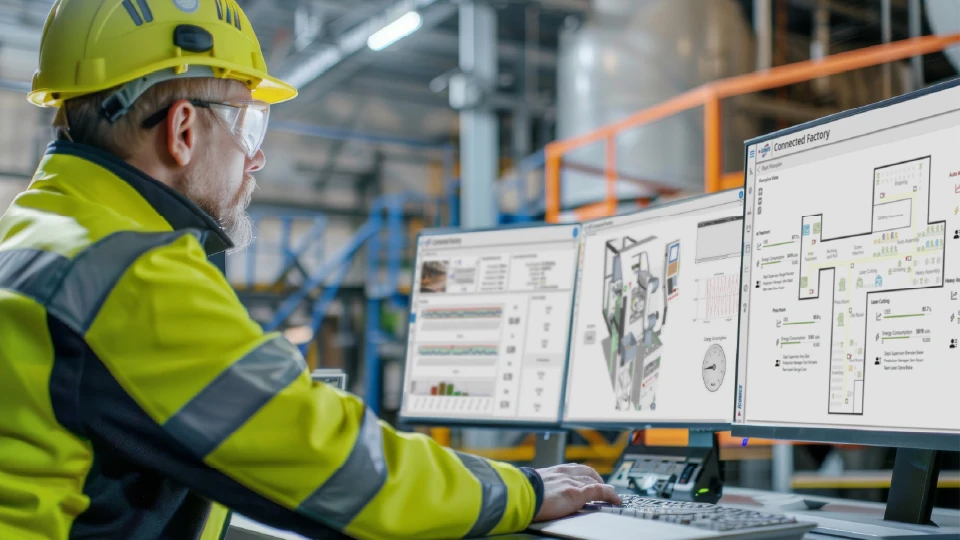

Understanding Digital Transformation & Assessing Where You Are on This Journey

Digital transformation is the process, many call it a journey, of incorporating digital solutions, strategies, and advanced technologies into traditional industrial factories/processes to bring about smart industrial factories/processes with greatly improved operations, productivity and work efficiency. It's a game changer for achieving operational optimization and improving your business model - which is why it’s crucial to assess where you are in this journey and to have the best plan in place.

New Industrial Apps & Platforms Make a Digital Future Possible for All Companies, No Matter the Size

This blog explores how the rise of micro cloud apps is reshaping the industrial software landscape—especially for small and mid-sized companies—by comparing it to the evolution of mobile gaming. It contrasts traditional SCADA platforms with emerging single-use cloud apps, highlighting trends in time-to-value, cloud adoption, and accessibility, and shares how Mitsubishi Electric Iconics Digital Solutions is adapting to serve this expanding market segment.

Achieving Connectivity to ALL Systems – the #1 Challenge of Digital Transformation

Industrial organizations can achieve a connectivity solution that gives them the ability for all their disparate devices, for all their disparate hardware from all the different vendors to talk, thus establishing interoperability and reliable communication. This connectivity is achievable with one leading solution, the Takebishi DeviceXPlorer OPC Server. This software is a OPC server software suite that provides connectivity with control devices in discrete manufacturing, process building automation, and control and operations environments and provides both the import of tag definitions and the related expressions in an ISA-95 hierarchical format and also combines this technology with another breakthrough in the market, the standardization of industrial names for data, thus making it a futureproofed technology. The Takebishi DeviceXPlorer OPC Server is integrated into the Mitsubishi Electric Iconics Digital Solutions GENESIS64 software suite and IoTWorX environment and is also available separately. Additionally, it allows direct communication between GENESIS software, and other applications, with the actual physical equipment and machinery on your production floor, providing you with the ability to monitor and control your facilities, factories, and processes.

Industry 4.0 Fundamentals and Technical Innovations That Enable Digital Transformation

Keeping up with and understanding the technology and related terminology of digital transformation and Industry 4.0 (the fourth Industrial Revolution) might be daunting. However, if you're in industrial manufacturing or industrial processing, it’s important to know the basics and benefits of these. What follows is an explanation about the technical innovations that enable digital transformation in the context of Industry 4.0 and how all of these relate to industrial manufacturing and industrial processes.

English

English

Czech

Czech

German

German

French

French

Italian

Italian

Japanese

Japanese

Polish

Polish