Category: Manufacturing

FLSmidth

Copenhagen, Denmark

Category: Manufacturing

Copenhagen, Denmark

“The GENESIS Suite is a critical application in our portfolio regarding the health of our customers’ assets. We use Mitsubishi Electric Iconics Digital Solutions' GENESIS in our Monitoring Center to monitor and report on potential failures in our customers’ assets which in turn allows us to quickly respond and fix any problem. ”

Since 1882, FLSmidth has been providing innovative engineering, equipment, and service solutions to the global mining and cement industries, so their customers can improve operational performance, thereby reducing costs and environmental impact.

With the belief that even a small discovery can lead to great potential, the company has used their experience, expertise, and passion to change the rules for processing natural resources to help create the world we live in today.

Additionally, FLSmidth is committed to building a sustainable future and plays a key role in delivering sustainable productivity to the mining and cement industries through their MissionZero initiative, which is designed to enable their customers to move toward zero emission by 2030. The company aims to achieve this goal by embracing advanced technology, digital solutions, and strong partnerships.

Today, FLSmidth provides their customers with increased output and quality, reduced total cost of ownership (TCO), and optimized productivity, which they refer to as Sustainable Productivity.

“The GENESIS Suite is a critical application in our portfolio regarding the health of our customers’ assets. We use Mitsubishi Electric Iconics Digital Solutions' GENESIS in our Monitoring Center to monitor and report on potential failures in our customers’ assets which in turn allows us to quickly respond and fix any problem. ”

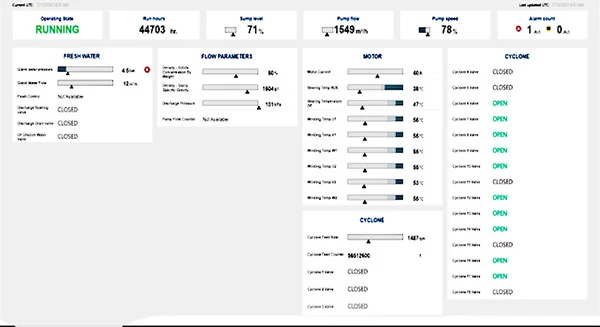

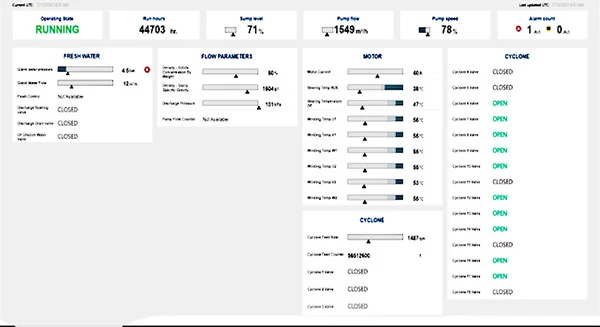

Pump Dashboard Overview

Pump Dashboard Overview

FLSmidth operates multiple worldwide Monitoring Control Centers from which its teams can remotely and centrally monitor the asset health of its global Mining and Cement customers. The company was primarily seeking a solution that would:

FLSmidth chose Mitsubishi Electric Iconics Digital Solutions because it develops IoT and cloud-ready solutions that:

Pump Dashboard Overview

Pump Dashboard Overview

Recirculation Historical Data

Recirculation Historical Data

Recirculation Historical Data

Recirculation Historical Data

Predictive Models KPI

Predictive Models KPI

FLSmidth saw significant benefits after deploying GENESIS64, the automation and digitalization software from Mitsubishi Electric Iconics Digital Solutions. The company can now:

Example in action: Using a GENESIS64 dashboard, the company identified an oil leak in a customer’s crusher and prevented significant downtime.

GENESIS integrates seamlessly with the Azure platform, making it highly scalable and reliable. FLSmidth leverages GraphWorX64 to create dashboards for monitoring key metrics, such as:

Additional capabilities include:

Predictive Models KPI

Predictive Models KPI

Mitsubishi Electric Iconics Digital Solutions plays a critical and compelling role with respect to FLSmidth’s ability to remotely monitor their customers’ assets. This capability allows the company to assess the performance of their customers’ assets and generate reports that outline these results.

FLSmidth plans to expand its use of GENESIS64 Hyper Alarming to enhance monitoring capabilities even further. Leveraging advancing IoT connectivity, the company aims to increase coverage from 230 to roughly 400 plants, encompassing about 10,000 assets.