Category: Food and Beverage

United Biscuits

Glasgow, Scotland

Category: Food and Beverage

Glasgow, Scotland

“The GENESIS software is so easy to use. DataWorX™ is a very understated component with a great deal of power. The graphics that can easily be created in GraphWorX™ are outstanding.”

Quality is a primary concern for McVitie’s, part of United Biscuits (UB). At their plant in Tollcross, Glasgow, they have developed a control technology, which puts them in the front line on this point, as well as reinforcing the approach to innovative solutions encouraged across the business. The question was how to translate the intelligence of more than 30 years experience into an automatic, high-performance process control system, which is user friendly and could be retrofitted on the existing equipment.

“The GENESIS software is so easy to use. DataWorX™ is a very understated component with a great deal of power. The graphics that can easily be created in GraphWorX™ are outstanding.”

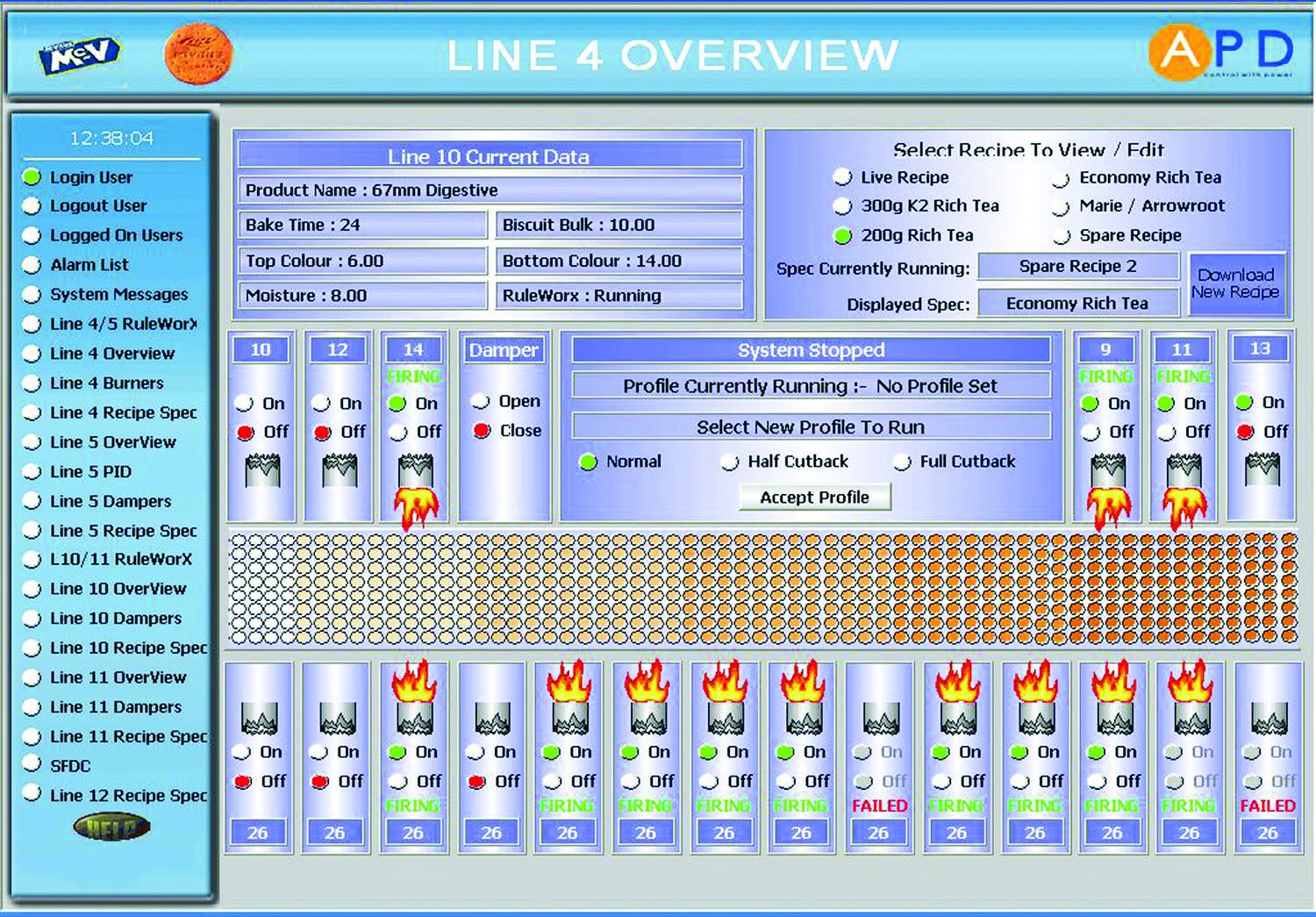

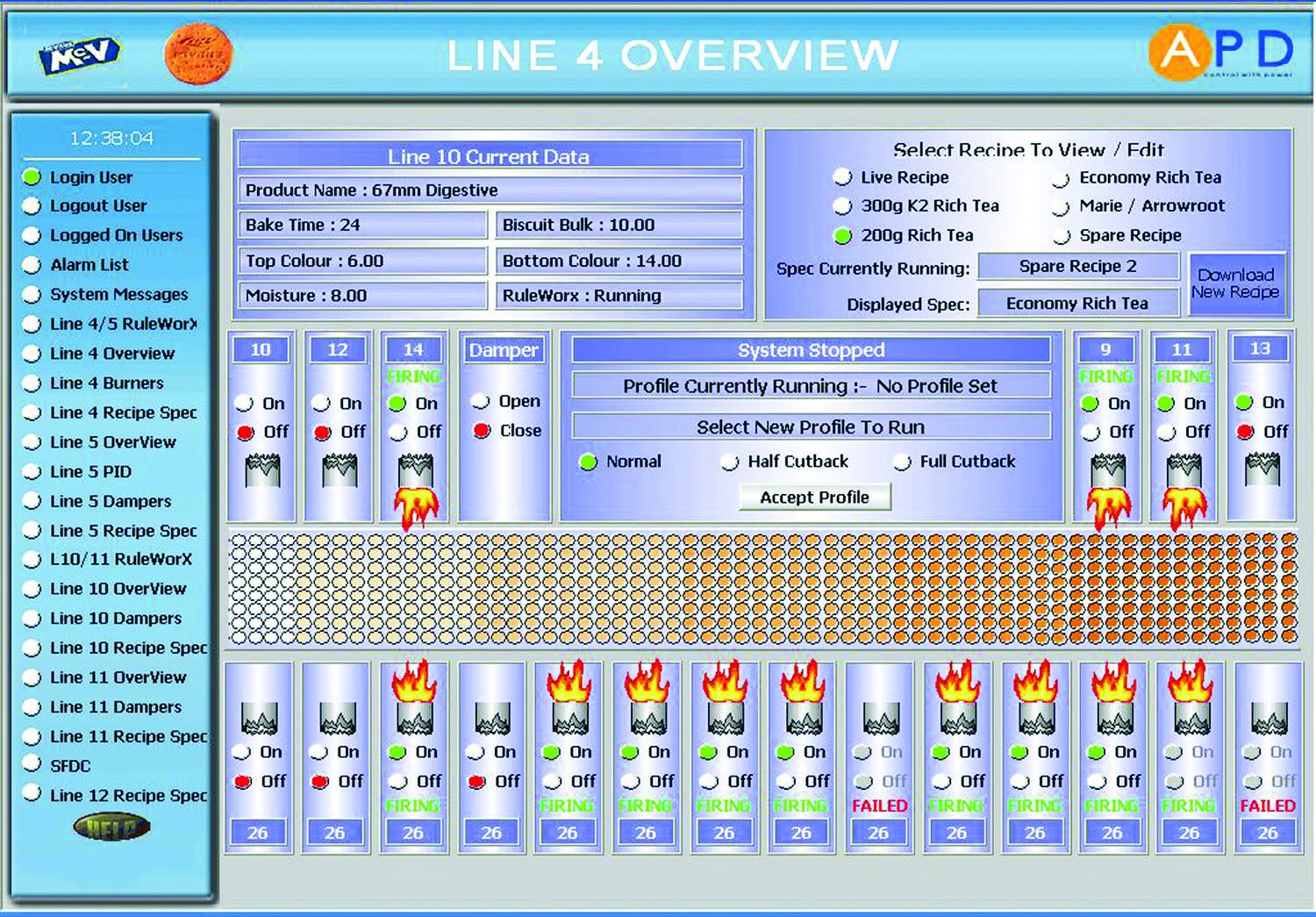

Burner Control Screen

Burner Control Screen

The software selected for this application is based on GENESIS. On the production line, which makes their Rich Tea biscuits, they have a multizone oven that produces thousands of biscuits per hour. Before automation was in place, an operator with many years of experience governed the control of this oven, and a great deal of skill and high-quality biscuits were produced. The knowledge of this operator was documented and formulated into a set of rules for adjusting the oven control based on the quality of the biscuits exiting the oven. Engineers from Mitsubishi Electric Iconics Digital Solutions UK Ltd., working alongside McVitie’s technical staff, developed a software system to execute the rules and automatically make the control adjustments within the oven.

Burner Control Screen

Burner Control Screen

United Biscuits Production Line

United Biscuits Production Line

The data acquisition module, DataWorX™, acquires and manipulates these data, which are then accessed by the HMI, GraphWorX™, and a rules-based module. The rules-based module built into GENESIS then applies the rules developed from more than 30 years experience of the operators and outputs the instructions, via the scripting module ScriptWorX™, to the PLC, which controls the burners and temperatures in the oven zones. GraphWorX also performs the other more traditional SCADA functions of graphical display of data and process elements. This includes the screens to select which one of the products is to be manufactured.

United Biscuits Production Line

United Biscuits Production Line

Main Control Screen at UB - McVitie’s

Main Control Screen at UB - McVitie’s

For each different product there is a different set of rules to apply to the oven control. However, GENESIS makes this adjustment automatically for whichever product is selected. It also displays the rules, which are being implemented at any particular time. All rule modifications are password-protected, online through the operator’s terminal.

Main Control Screen at UB - McVitie’s

Main Control Screen at UB - McVitie’s

By utilizing these methods for control of the baking process. United Biscuits is now able to put into practice new ideas within the process itself to further improve their product and to provide a competitive advantage over their competitors. The actual recipe for the fine control of the oven is top-secret to McVitie’s, but now they make a higher-quality biscuit and line efficiency has improved by 2.5%.

United Biscuits is delighted with its success on controlling this line, and it has taken GENESIS as their standard HMI/SCADA software, with installations planned throughout the UK and Europe. The software was integrated by APD of Annan, Dumfriesshire UK. APD also provided on-site training for the operators and engineering personnel.