Category: Manufacturing

VEC Technology

Greenville, PA / Little Falls, MN, United States

Category: Manufacturing

Greenville, PA / Little Falls, MN, United States

“GENESIS gave us unparalleled flexibility for creating the content we needed. We just plugged [it] onto our system to communicate with all our existing hardware interface drivers and software. With its GraphWorX tool, our HMI visualizations are much more intuitive and it was easy to do it myself.”

VEC Technology’s Greenville, PA, location provided custom composite manufacturing. Its then-parent company, J&D Acquisitions, also owned Larson Boats, a Little Falls, MN, manufacturer of recreational boat hulls that utilized the VEC process.

This process was described as “a patented, state-of-the-art, computer-controlled manufacturing process that guarantees that every part was made to the most exacting standards of fit and finish, resulting in parts with unparalleled beauty and unprecedented quality.”

VEC Technology considered itself a one-stop shop for OEMs, providing:

The Pennsylvania facility included seven molding stations. The company stated that manufacturing cells using its patented Floating Mold technology delivered “low-cost, high-quality, extremely accurate, closed-mold solutions.”

VEC Technology reported achieving “great success” in the following markets:

Larson Boats, itself a customer of VEC Technology, could process boat hulls in the 17–24 ft range at its Minnesota location, which included eight molding stations and an automation mix plant.

“GENESIS gave us unparalleled flexibility for creating the content we needed. We just plugged [it] onto our system to communicate with all our existing hardware interface drivers and software. With its GraphWorX tool, our HMI visualizations are much more intuitive and it was easy to do it myself.”

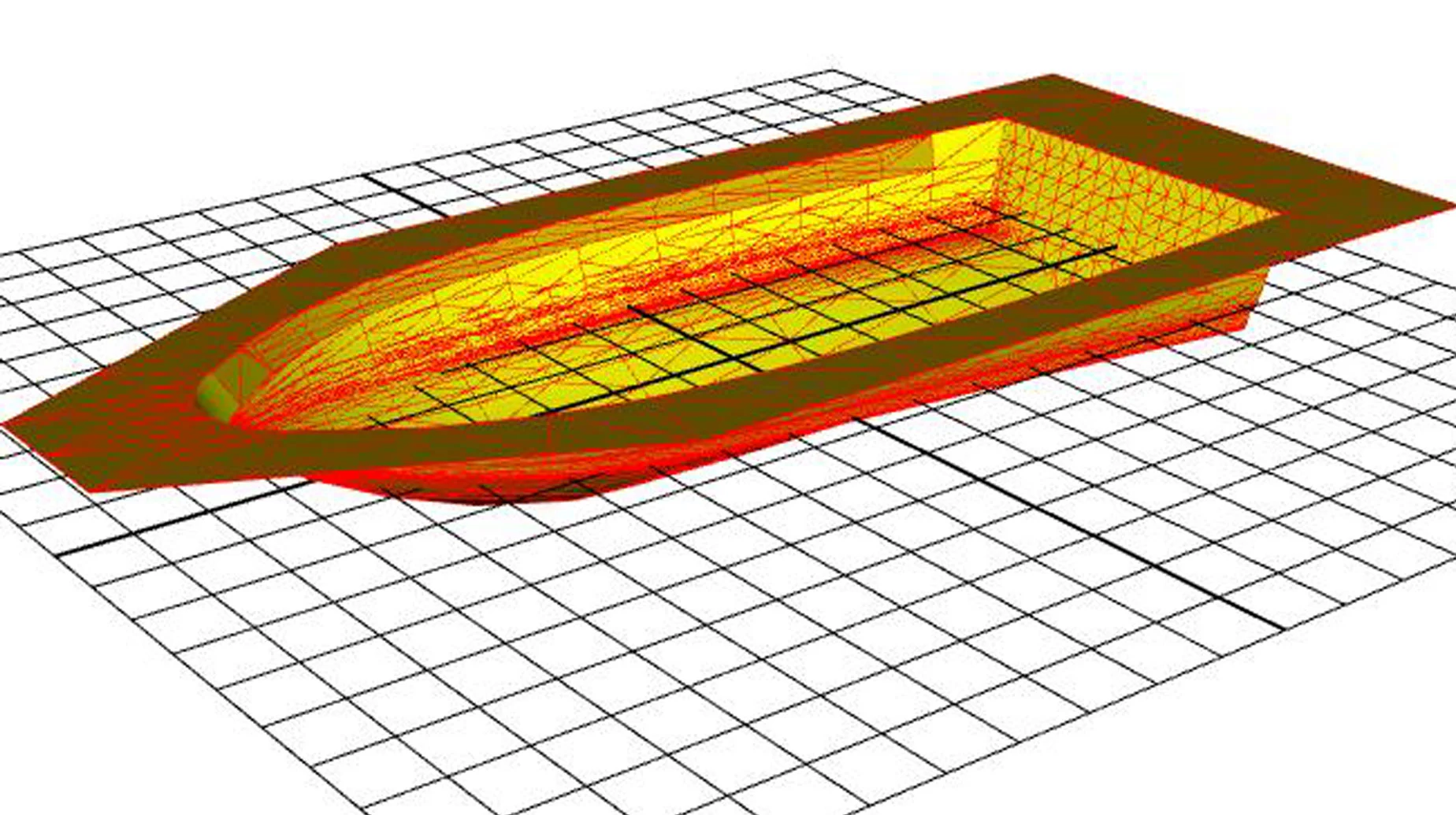

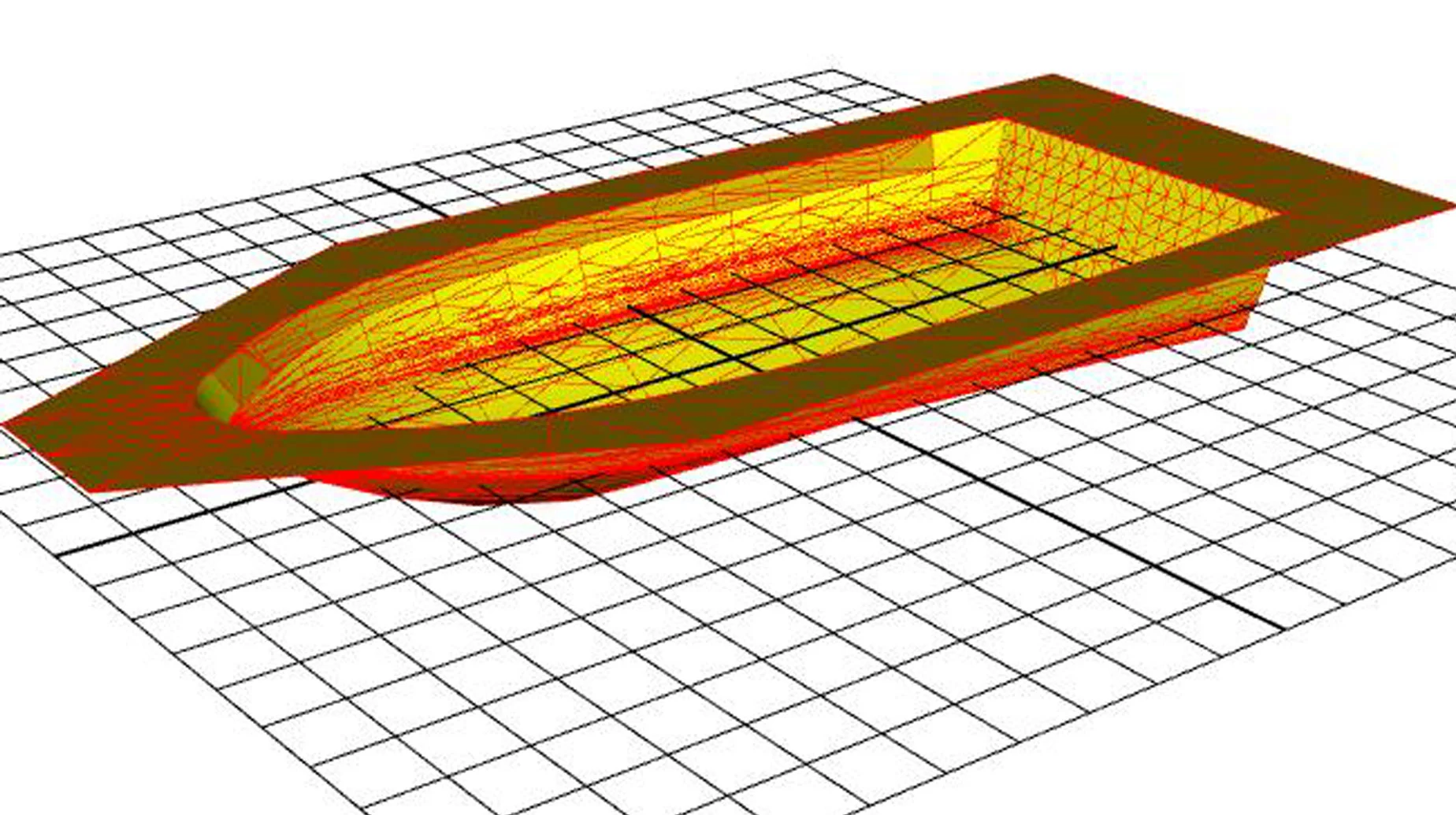

A 3D Rendering of a Boat During Construction Visualized Through GENESIS64/GraphWorX64

A 3D Rendering of a Boat During Construction Visualized Through GENESIS64/GraphWorX64

VEC Technology selected:

A 3D Rendering of a Boat During Construction Visualized Through GENESIS64/GraphWorX64

A 3D Rendering of a Boat During Construction Visualized Through GENESIS64/GraphWorX64

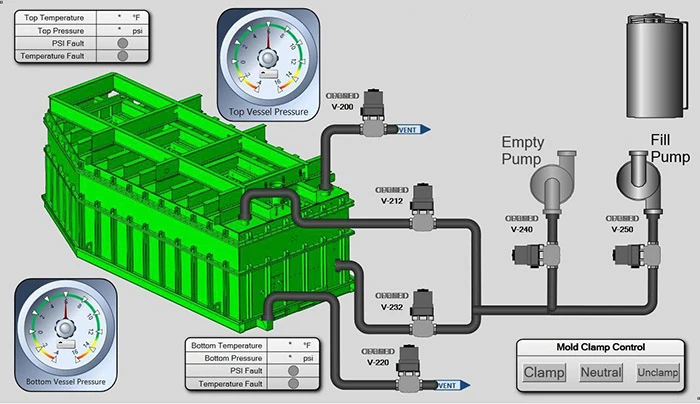

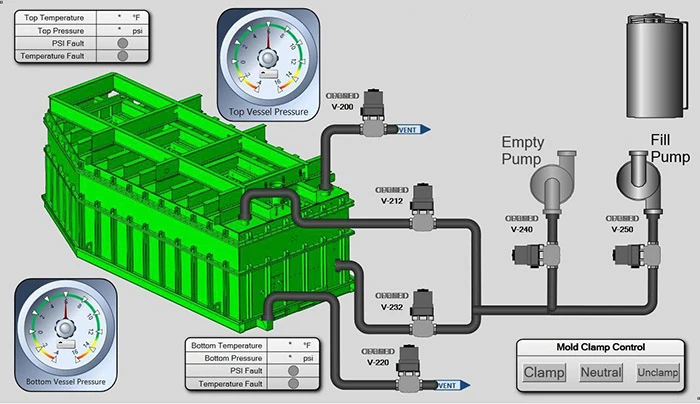

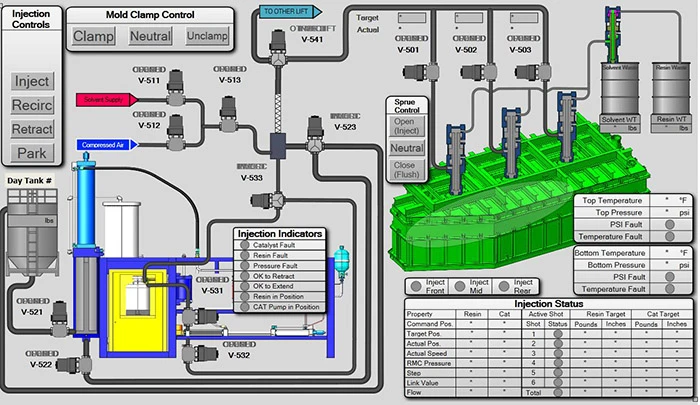

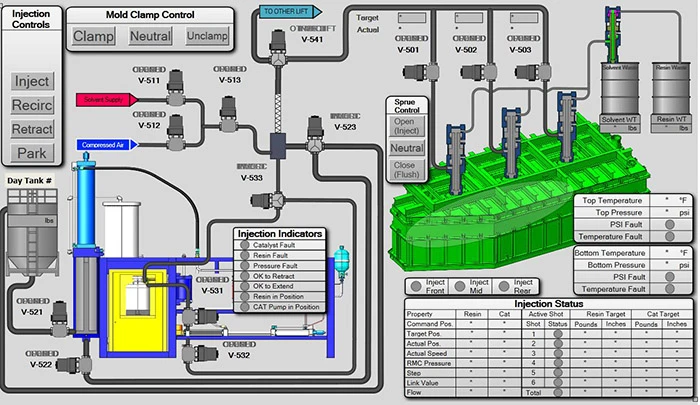

A VEC Technology Fluid Transfer Control Screen

A VEC Technology Fluid Transfer Control Screen

VEC Technology required an HMI/SCADA solution with data bridging, reporting, and archiving capabilities. The system needed to operate over the Web, integrate with the OPC communications protocol, and interface directly with the company’s product databases.

The solution would control and monitor VEC Technology’s patented closed molding operations and manage parameters based on several criteria, including:

In addition, the company required long-term storage of multiple key parameters to support product warranty information. VEC Technology sought future-proof technology that could:

The company also aimed for a “single vendor” approach to reduce both the number of automation interfaces and the extra support staff needed to maintain multiple systems.

The engineering team allowed a 10-month development cycle for the first installation, ensuring in-house personnel would gain familiarity with the selected HMI/SCADA solution. The software needed to interface with multiple systems and hardware, including:

Each molding station required the HMI/SCADA software to handle approximately 1,200 tags.

For this project, VEC Technology maintained four servers and 16 client stations. The company also used several Microsoft applications, including:

Two competitor solutions were considered, along with the option of keeping existing software from other providers. Ultimately, VEC Technology chose Mitsubishi Electric Iconics Digital Solutions.

A VEC Technology Fluid Transfer Control Screen

A VEC Technology Fluid Transfer Control Screen

Injection Control Screen

Injection Control Screen

VEC Technology wanted a single-source HMI/SCADA program that would:

Additionally, the company required software that could:

GENESIS64 now provides what VEC Technology describes as “spectacular” and “rich” 3D graphics with “superb resolution” and an enhanced operator experience, fully leveraging the company’s CAD investments. The company now uses a single database for data logging, while GENESIS BridgeWorX software has eliminated numerous custom VBA scripts.

As a result, VEC Technology reduced its operational staff needs—from eight employees tasked with maintaining multiple systems to just two employees maintaining the new unified system.

Looking ahead, the company plans to expand its GENESIS-integrated application by implementing downstream post-molding stations to input quality data directly into databases, eliminating the need for paper forms.

Injection Control Screen

Injection Control Screen

An Operator Monitoring Hull Production

An Operator Monitoring Hull Production

VEC Technology and Larson Boats required an HMI/SCADA solution that would allow them to continue delivering customized options for their own customers while improving efficiency and reliability. The GENESIS64 HMI/SCADA suite, with its wide range of integrated manufacturing intelligence tools, proved to be the ideal fit—tailored to their unique processes and scalable to support evolving requirements.

By consolidating systems, streamlining operations, and enhancing visualization, GENESIS64 has positioned VEC Technology and Larson Boats to deliver higher-quality products, reduce operational complexity, and maintain a competitive edge well into the future.

An Operator Monitoring Hull Production

An Operator Monitoring Hull Production