What You’ll Learn

You’ll discover how automation and digital transformation are reshaping the oil and gas sector in Southeast Asia and how the GENESIS SCADA and HMI platform by Mitsubishi Electric Iconics Digital Solutions enables companies to connect, visualize, and optimize operations across the energy value chain.

You’ll learn how to:

- Understand the challenges driving operational change across upstream, midstream, and downstream segments

- See how industrial digital transformation improves efficiency, safety, and sustainability

- Explore how GENESIS helps energy companies capture and unify data and drive better decision-making

- Discover real-world results from leading oil and gas organizations

Rethinking Energy Operations in Southeast Asia

Southeast Asia’s oil and gas industry is at a crossroads. Energy demand continues to rise, but companies face a tightening balance between production, cost, and carbon reduction. Offshore wells are aging, skilled labor is scarce, and environmental regulations are growing stricter.

At the same time, the region’s geography, from Indonesia’s dispersed offshore fields to Thailand’s refining hubs, makes operations highly decentralized. Many companies still depend on isolated control systems, manual reporting, and delayed data that limit their ability to respond quickly when problems arise.

Digitalization has become the new engine of operational excellence, enabling oil and gas companies to move from reactive control to proactive, insight-driven performance. By connecting equipment, systems, and people through real-time data and intelligent analytics, energy companies can:

- Capture and manage operational data to establish a single source of truth across systems

- Monitor assets across multiple locations from a single dashboard

- Detect and resolve issues before these lead to downtime or safety risks

- Optimize energy use and reduce emissions through predictive insights

- Enable faster, smarter decisions that support both efficiency and sustainability goals

The next step is choosing a platform that can turn these capabilities into measurable outcomes, a SCADA and HMI platform like GENESIS by Mitsubishi Electric Iconics Digital Solutions.

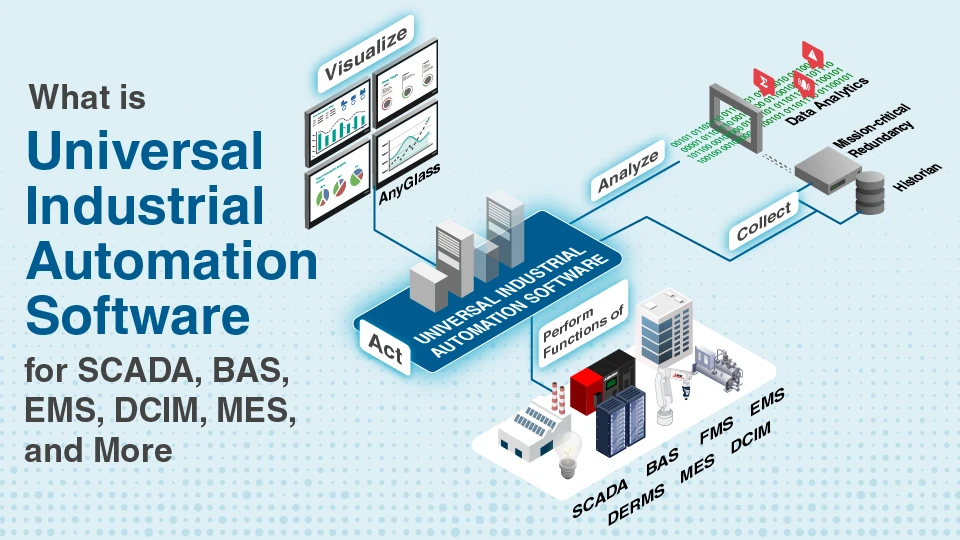

How GENESIS Powers Digital Transformation in Oil and Gas

GENESIS is designed to help oil and gas companies connect, visualize, and optimize operations across the entire energy value chain. By unifying data acquisition, data management, and real-time visualization within one intelligent environment, this SCADA and HMI platform turns industrial data into actionable insight that drives efficiency, safety, and sustainability.

With GENESIS, organizations can:

- Integrate and visualize operations in real time

Consolidate data from distributed assets, field equipment, and control systems into a unified dashboard. Engineers and operators can view performance metrics, trends, and alerts from a single interface instead of navigating multiple systems. - Acquire, manage, and analyze high-speed data

Use the built-in industrial historian to log reliable, high-frequency data that captures operational events in milliseconds, enabling detailed trend analysis, root cause identification, and performance optimization. - Automate reporting and alarm management

Streamline event notifications, alarms, and reporting workflows to help teams respond faster to issues, maintain compliance, and document performance without manual intervention. - Ensure secure, scalable connectivity

Support standard industrial protocols such as OPC UA, MQTT, BACnet, and Modbus to ensure interoperability with existing systems and seamless scalability across local, remote, and cloud environments. Through Mitsubishi Electric’s partnership with Takebishi, GENESIS also integrates with DeviceXPlorer OPC Server, a trusted solution for industrial connectivity and remote data acquisition. DeviceXPlorer enables secure, reliable communication between PLCs, controllers, and SCADA systems, simplifying integration across diverse assets and locations. - Enable mobile and remote access

Provide secure web and mobile interfaces that allow teams to monitor and manage assets from anywhere, whether in the field, at headquarters, or offshore. - Improve energy efficiency and sustainability

Leverage real-time sensor data to track energy use, detect inefficiencies, and reduce emissions, advancing corporate ESG goals. - Support intelligent, data-driven decision-making

Apply advanced visualization and analytics to transform raw industrial data into meaningful intelligence that drives predictive maintenance, asset optimization, and operational excellence.

In practice, technology alone does not deliver transformation. Successful digital initiatives in oil and gas depend on how effectively advanced platforms are implemented, integrated, and scaled across complex operational environments, a responsibility typically led by system integrators (Sis). Drawing on firsthand delivery experience, SIs offer a valuable perspective on how GENESIS performs in real-world deployments.

Industry Insight from a Trusted System Integrator

System integrators working across oil and gas operations consistently point to the practical advantages of GENESIS in real-world deployments. Their perspective reinforces the platform’s strength in delivering unified visualization, streamlined workflows, and data-driven decision-making. One SI summarized the platform’s value in this way:

“GENESIS from Mitsubishi Electric Iconics Digital Solutions has proven to be the SCADA and HMI platform of choice for the oil and gas industry. The platform delivers a single pane of glass across systems, unifying visualization, real-time data, and analytics, so engineers and operators gain the clarity they need to improve efficiency and make faster, more informed decisions.”

Kevin Jordan, Business Development Manager, Process Control Dynamics, Inc.

Upstream: Driving Smarter Exploration and Production

In upstream operations, every second counts. Field engineers and control room operators need visibility into wells, pumps, and compressors scattered across remote sites.

GENESIS uses a built-in industrial historian to capture and manage high-resolution operational data, which then feeds the platform’s real-time visualization and analysis to optimize well performance, anticipate failures, and improve safety.

For example, an offshore platform in Malaysia could use GENESIS dashboards to track wellhead pressure, monitor equipment health, and receive immediate alerts when readings deviate from normal ranges, reducing unplanned downtime and improving compliance with safety standards.

Midstream: Securing and Simplifying Pipeline Operations

Across thousands of kilometers of pipelines, visibility is also essential. Yet many operators still rely on fragmented monitoring systems and delayed field reports, making it difficult to detect leaks or respond quickly to maintenance issues.

GENESIS provides unified, encrypted connectivity that consolidates flow, pressure, and temperature data across vast pipeline networks. Operators gain a single source of truth for operational performance, improving decision-making, risk management, and efficiency.

Downstream: Refining Efficiency and Sustainability

In downstream operations, efficiency and environmental performance go hand in hand. Refineries and petrochemical facilities must balance throughput with energy management and emissions control.

GENESIS helps operators integrate plant-wide data, automate reporting, and use real-time analytics to improve yield, reduce energy waste, and maintain compliance.

For example:

- A refinery in Vietnam could use GENESIS to analyze energy consumption across process lines.

- A fuel retailer in Thailand could expand monitoring across hundreds of stations without additional licensing costs, thanks to GENESIS’s unlimited scalability.

- A petrochemical facility in Singapore could leverage GENESIS data insights to optimize batch processing and reduce flare events, supporting national sustainability targets.

The impact of these capabilities becomes even clearer when seen in action. One example comes from Aksa Natural Gas Distribution, which modernized its operations using GENESIS.

Real-World Example: Aksa Natural Gas Distribution

Aksa Natural Gas Distribution, based in Istanbul, operates one of Turkey’s largest gas networks, spanning 34,000 kilometers and serving over 4 million subscribers. The company manages hundreds of Regulating and Metering Stations (RMSs) that reduce and regulate gas pressure, measure flow, and ensure the safe distribution of natural gas across 27 provinces.

Aksa faced several challenges typical of large-scale gas utilities. Each RMS type (A, B, or C) had its own pressure class and configuration, requiring continuous monitoring of critical parameters such as outlet pressure and gas quality. The existing systems were fragmented, with data spread across local displays and PLCs. Operators needed a centralized platform to gather both digital and analog station data, manage thousands of alarms, and issue timely notifications to field teams.

Moreover, Aksa needed to meet national and international safety standards by maintaining precise gas odorization and pressure levels. Any deviation, such as pressure dropping below 15 bar or rising above acceptable limits, could cause service disruptions or safety risks. The company also sought to improve accuracy at its 1,400 smaller RMS stations, where costly chromatograph devices were not feasible. These sites relied on Electronic Volume Correctors (EVCs) for gas quality data, which had to be updated and written to the central system accurately and efficiently.

To address these challenges, Aksa implemented GENESIS. The platform provided a unified environment for real-time monitoring, visualization, and alarm management across Aksa’s entire network.

Aksa achieved the following results:

- Unified monitoring and visualization of more than 120,000 active tags

- Real-time alarm management and event notifications for faster response

- GIS-based asset tracking and map-based operational displays

- Connection of equipment from multiple vendors using GENESIS and DeviceXPlorer OPC Server, eliminating silos, reducing downtime, and enabling real-time data flow

- Significant reduction in engineering time—from hours to seconds—when configuring new stations

The result: faster deployment, improved accuracy, and measurable operational savings. GENESIS now underpins Aksa’s growing network, supporting its mission to deliver reliable, efficient, and safe energy to millions of customers.

You can read the full success story here.

Building the Future of Energy Operations

The oil and gas industry’s future depends on its ability to adapt, which means embracing digital transformation not just to stay competitive but to lead responsibly. GENESIS makes that transformation possible by connecting people, systems, and insight into a single, intelligent platform.

From production fields to refinery floors, this SCADA and HMI platform helps energy companies unlock efficiency, improve safety, and build a more sustainable energy future

To help organizations explore what digital transformation can achieve in the oil and gas sector, here are answers to some of the most common questions about smart automation, data management, and GENESIS.

Frequently Asked Questions

What is digital transformation in oil and gas?

Digital transformation in oil and gas refers to using connected technologies such as SCADA, sensors, and analytics to modernize operations, improve decision making, and enhance safety, efficiency, and sustainability.

How does GENESIS support real-time data management?

GENESIS integrates data acquisition, management, and visualization into a single environment. Its built-in historian captures and stores high-speed operational data, enabling teams to analyze trends, detect anomalies, and optimize performance.

Can GENESIS work with existing automation systems?

Yes. GENESIS supports open communication standards including OPC UA, MQTT, Modbus, and BACnet, ensuring seamless integration with legacy systems and third-party devices.

How does GENESIS improve energy efficiency and ESG performance?

Real-time monitoring of energy consumption and emissions helps operators identify inefficiencies and reduce waste. These insights enable measurable progress toward sustainability and corporate ESG goals.

Drive Digital Transformation in Your Organization

Accelerate your company’s industrial digital transformation with GENESIS by Mitsubishi Electric Iconics Digital Solutions.

Down load the GENESIS brochure to explore the platform’s full capabilities, or contact one of our experts to discuss how GENESIS can help your organization optimize operations, improve efficiency, and achieve smarter, more sustainable energy outcomes.

English

English

Czech

Czech

German

German

French

French

Italian

Italian

Japanese

Japanese

Polish

Polish