Category: Water and Wastewater

Tefal SAS Factory Sewage Network

Rumilly, France

Category: Water and Wastewater

Rumilly, France

“Anything is possible with GENESIS from Mitsubishi Electric Iconics Digital Solutions. The only limit is your imagination.”

Groupe SEB (Société d’Emboutissage de Bourgogne) is a large French consortium that produces small appliances and is the world’s largest manufacturer of cookware. In an effort to move toward a circular economy, the company is committed to intensifying innovations while at the same time aligning itself with an environmental strategy that combats climate change.

One of Groupe SEB’s notable brands is Tefal S.A.S, a known French cookware and small appliance manufacturer. Tefal S.A.S operates a manufacturing factory in Rumilly, France which also includes an extensive sewage network.

“Anything is possible with GENESIS from Mitsubishi Electric Iconics Digital Solutions. The only limit is your imagination.”

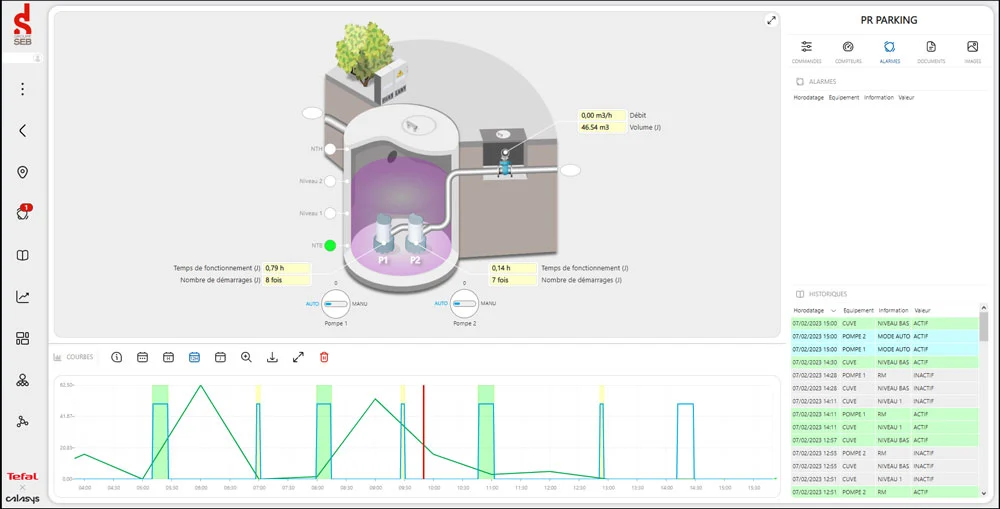

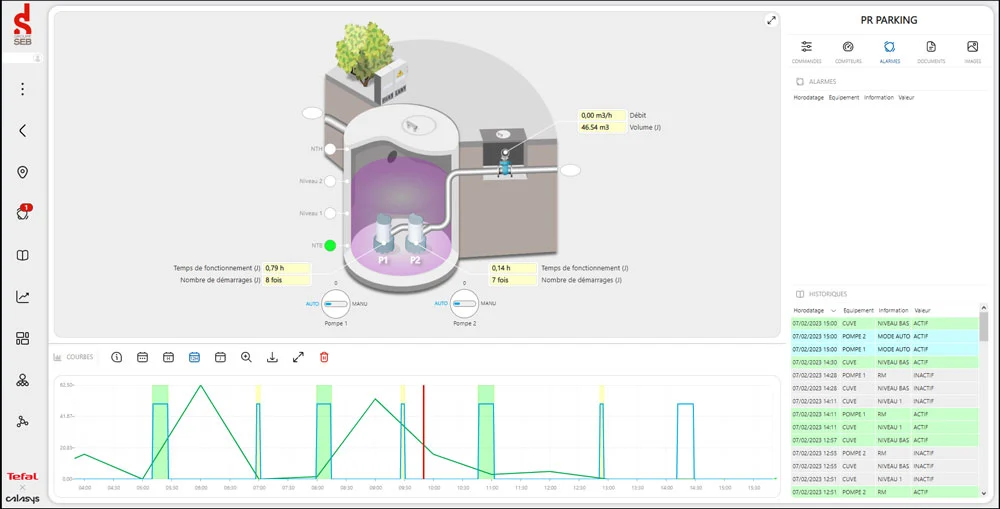

View of the Lift Station

View of the Lift Station

Tefal sought to implement a modern supervisory control solution for its sewage network at its Rumilly factory to improve real-time monitoring, streamline alarm response procedures, and reduce environmental risks.

Key project requirements included:

The project consisted of several phases, beginning with the reassembly of the eight discharge stations that make up part of the facility’s sewage network. The system integrator CALASYS was selected for their deep expertise in water treatment projects and their ability to advise Tefal throughout the design and implementation process.

The Tefal team chose automation and digitalization software from Mitsubishi Electric Iconics Digital Solutions for several important reasons. They were already familiar with GENESIS, having used it in other functional units at the Rumilly plant. Building on an existing platform ensured faster deployment, reduced training time, and smoother integration.

GENESIS was also selected for its ability to:

Additionally, CALASYS is a Gold Certified Mitsubishi Electric Iconics Digital Solutions system integrator with proven expertise and deep knowledge in deploying and using the software.

View of the Lift Station

View of the Lift Station

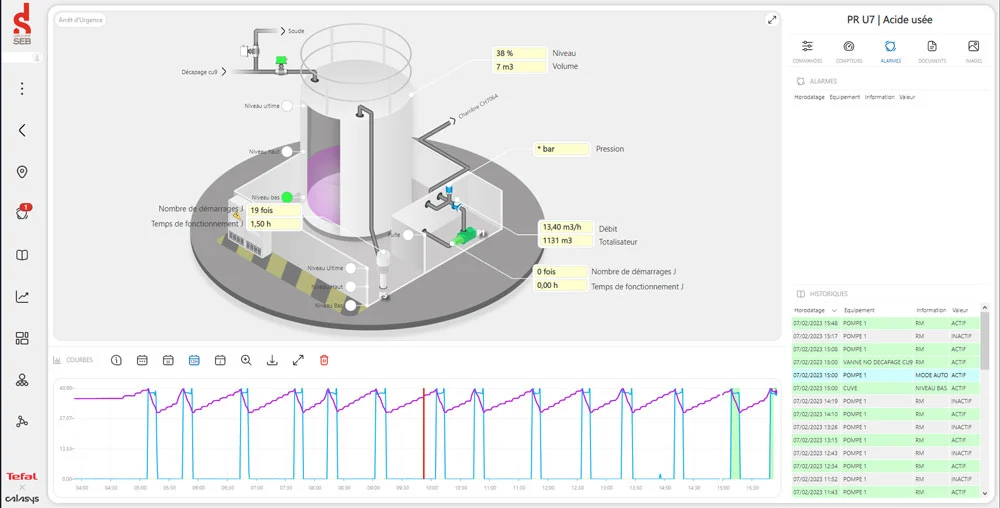

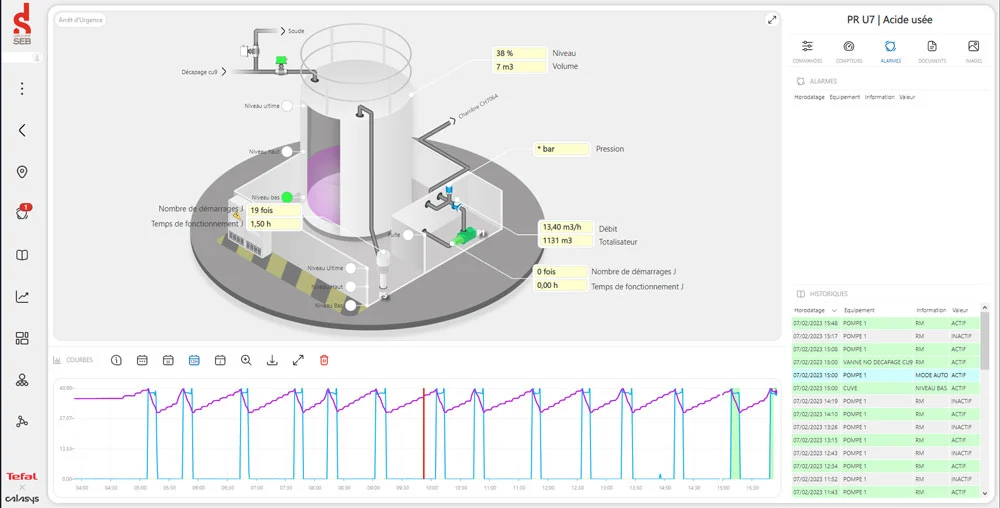

View of the Pre-Treatment Station

View of the Pre-Treatment Station

View of the Pre-Treatment Station

View of the Pre-Treatment Station

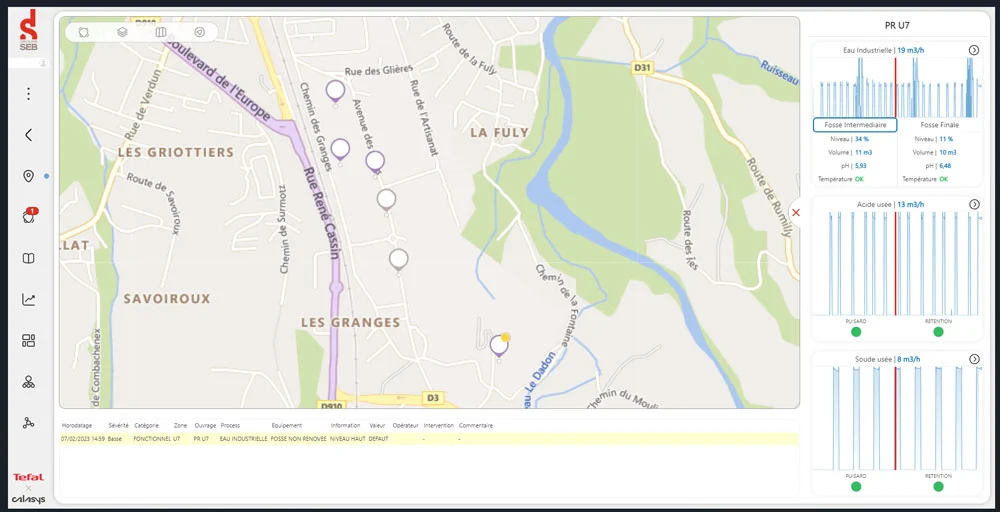

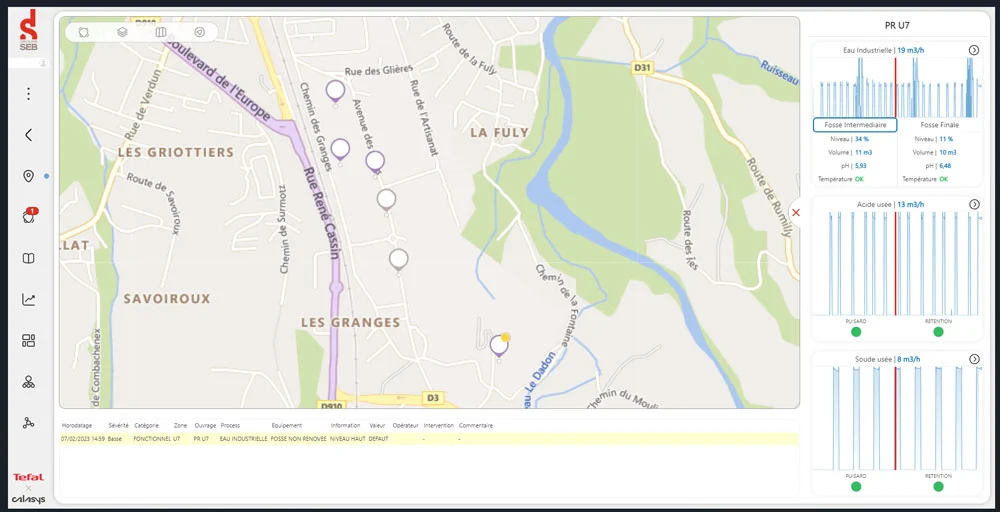

Hypervision of Different Workstations

Hypervision of Different Workstations

The Tefal factory experienced significant benefits from using GENESIS to monitor their sewage network, including:

Together, these improvements have helped Tefal streamline operations, enhance environmental protection, and optimize the overall performance of its sewage network.

Hypervision of Different Workstations

Hypervision of Different Workstations

The first phase of the project consisted of reassembling the eight discharge stations of the Rumilly site. By utilizing the template-friendly capabilities of Mitsubishi Electric Iconics Digital Solutions’ Bulk Asset Configurator, the team saved a substantial amount of time on the project completion. The next step of this project is to add the wastewater treatment plant which will use four additional PLCs on GENESIS64 SCADA.

The Clone Dynamic is a versatile tool within GraphWorX64 allowing users to create symbols in displays that are replicated and positioned automatically in real time to match the quantity of assets. This capability allows for significant project scalability and time savings for integration with GENESIS. Learn more.