Mitsubishi Electric Iconics Digital Solutions (MEIDS) turns it up to 11 with version 11 to go above and beyond what automation software is today. Customers get unparalleled value with GENESIS version 11’s advanced visualization, data-centric design, extensibility, connectivity, rapid deployment, and so much more. And version 11 is built on a history of quality and scalability – just like a mix of 5 new indie bands and the greatest rock bands of all time, keeping it modern, creating hits every year, continuing to take the stage, and taking things up to 11.

GENESIS Version 11 – an Automation & Digital Transformation Software That Turns It Up to 11

GENESIS Version 11 Boldly Goes Where No Automation Software Has Gone Before

Mitsubishi Electric Iconics Digital Solutions (MEIDS) boldly takes its latest version of GENESIS – version 11 – where no automation software has gone before. With version 11, MEIDS bravely sets a new standard for SCADA software. Organizations will be able to deploy a diverse array of digitalization project solutions quickly and efficiently. Whether it is enterprise-wide intelligent control systems and data historization, situational/operational awareness and notification platforms, or enterprise analytics, the GENESIS suite makes it all possible.

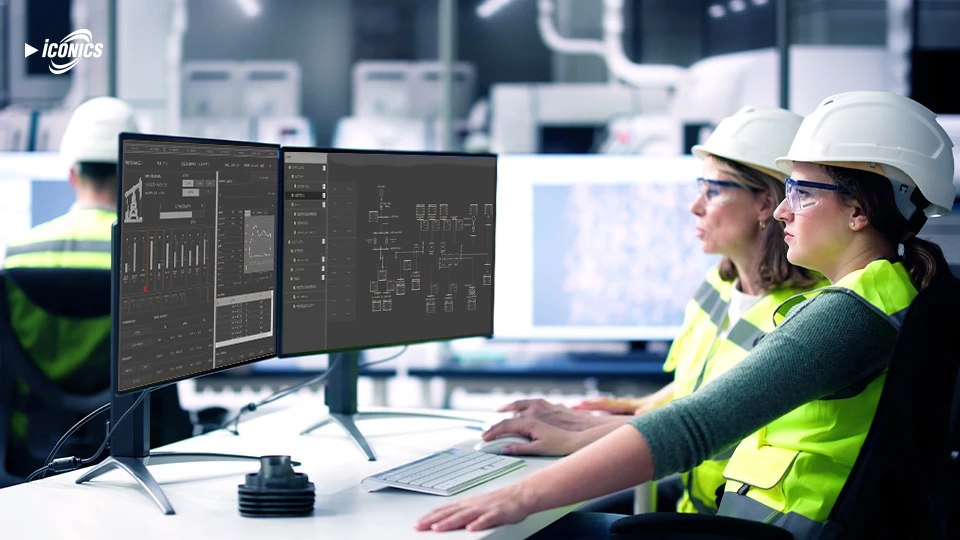

High Performance HMIs Key to Optimizing Operations

High performance HMIs have simpler designed graphic displays with standards-driven recommendations for navigation and presentation and monochromatic color schemes that provide clear and actionable information. Operators therefore do not waste time or make mistakes interpreting operational displays and in fact can do their job with more accuracy, efficiency, and ease. High performance HMIs like MEIDS GENESIS64 can be instrumental to running your industrial operations at the highest level. There is eloquence and beauty in simplicity, and this is true for high performance HMIs. And the same is true for GENESIS64.

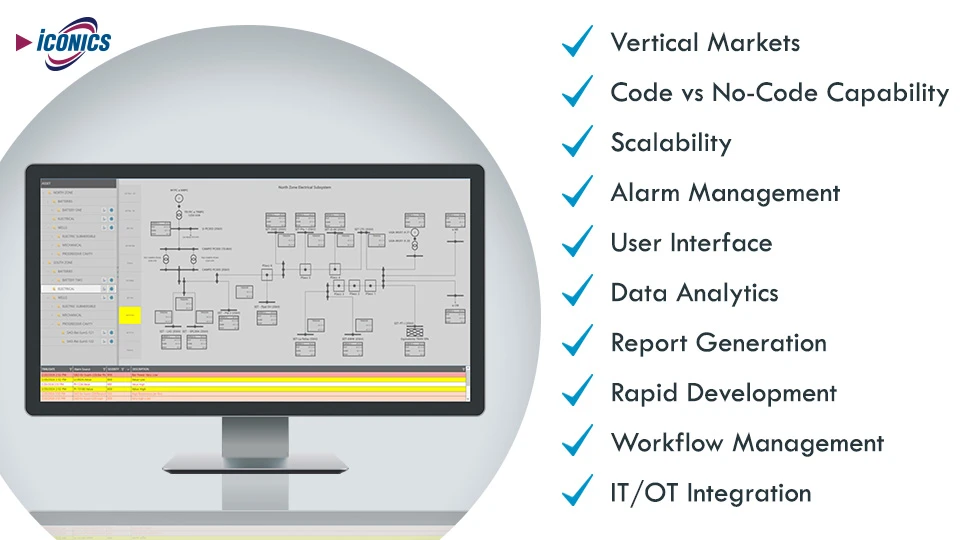

Choosing SCADA (Supervisory Control and Data Acquisition) - Selection Criteria and Guidelines

Selecting the right SCADA is a crucial decision that can significantly impact your manufacturing and infrastructure performance, reliability, and overall success of your IT and OT systems. Factors to consider include performance, reliability, redundancy, technical support, northbound and southbound protocol connectivity, flexibility, proven track record, distribution, compatibility, operating system support, pricing, licensing model, ease of use, vendor endorsement, and certifications. By carefully evaluating these and other criteria and considering the specific needs of your application, you can make an informed decision and choose the SCADA that best meets your requirements.

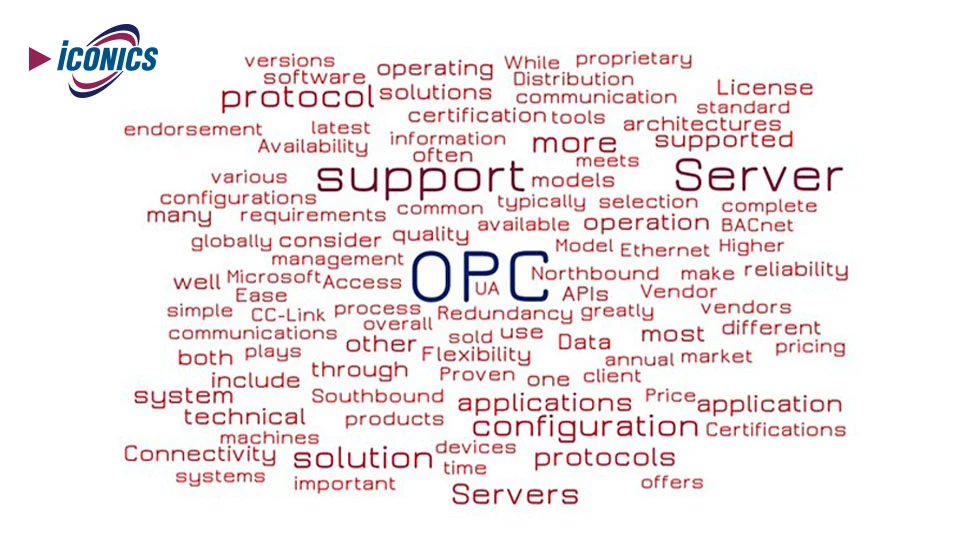

Criteria for Selecting an OPC Server

Selecting the right OPC Server is a crucial decision that can significantly impact the performance, reliability, and overall success of your control system. Factors to consider include performance, reliability, redundancy, technical support, northbound and southbound connectivity, flexibility, proven track record, distribution, compatibility, operating system support, pricing, licensing model, ease of use, vendor endorsement, and certifications. By carefully evaluating these criteria and considering the specific needs of your application, you can make an informed decision and choose the OPC Server that best meets your requirements.

How the EV Industry & Its Suppliers Can Use Automation Software to Lock in Sustainability

Given the serious and disturbing effects of climate change, we look to the EV industry and its suppliers as sustainability role models. It is therefore critical for these organizations to lock in sustainability in their manufacturing processes, and they can do this with modern advanced automation software like the GENESIS suite by Mitsubishi Electric Iconics Digital Solutions. With the real-time operational visualization they get, personnel can take data-driven actions to ensure continuous improvement for energy efficient, sustainable operations.

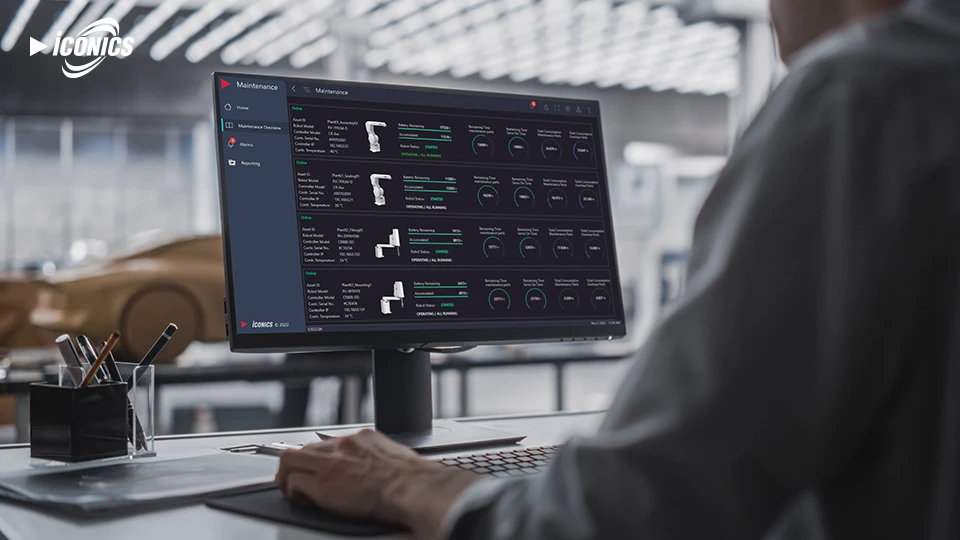

Suppliers for the Electric Vehicle Industry Can Transform Operations Through Predictive Maintenance

One way to ensure that the EV industry and its suppliers meet the rocketing demand for electric vehicles is to realize predictive maintenance. As a data-driven strategy that uses real-time insights to predict failures, predictive maintenance optimizes maintenance efforts allowing teams to perform maintenance only when necessary. The industry and its suppliers can achieve predictive maintenance with an A-team combination of Mitsubishi Electric’s AI predictive analytics and its GENESIS automation software.

Plug-n-Play: A Top SCADA Trend That Benefits the End Users

“Plug-n-play” no/low code SCADA systems have the necessary functionality and flexibility so that both system integrators and end users can manage and make the most out of these systems. More importantly, no/low code SCADAs benefit end users in many ways including ease of use, rapid development, lower costs, increased agility, and employee empowerment and innovation.

English

English

Czech

Czech

German

German

French

French

Italian

Italian

Japanese

Japanese

Polish

Polish