Category: Building Automation

Centre for Advanced Laser Applications

Garching, Germany

Category: Building Automation

Garching, Germany

“GENESIS has enabled us to create an ergonomic frontend for the control system and with KPIWorX, to create a smart digital signage solution for the entry to every experimental laser area.”

The Centre for Advanced Laser Applications (CALA) is a research facility located on the Research/High Tech Campus in Garching, Germany. As a location for interdisciplinary top-level research, CALA offers international physicists, physicians, and biologists a unique array of state-of-the-art laser technologies.

These scientists and researchers aim to develop sensitive and cost-efficient laser-based methods for the detection and therapy for cancer and other chronic diseases. Their hope is to develop early diagnosis as a key to the successful treatment of these illnesses.

They are also focusing on high-intensity X-rays for diagnostic biomedical imaging, laser-generated proton and carbon-ion beams for tumor therapy, and high-resolution laser-based infrared spectroscopy for blood and expired air analysis with the goal of providing risk-free screening procedures. Lastly, CALA research is concerned with maximizing patient health potential and recovery chances.

“GENESIS has enabled us to create an ergonomic frontend for the control system and with KPIWorX, to create a smart digital signage solution for the entry to every experimental laser area.”

CALA Control Center, photo credit: MESALOGIC

CALA Control Center, photo credit: MESALOGIC

Two high-tech laser sources, the ATLAS-3000 and the PFS-Pro, are installed in CALA’s state-of-the-art cleanrooms. The world’s first commercial Munich Compact Light Source (MuCLS)—a combination of a compact electron accelerator and lasers for generating X-rays—is in operation at the Munich School of Bioengineering Building (IMETUM) at the Technical University of Munich.

While MuCLS connects directly to its experimental area, the ATLAS and PFS-Pro are spatially separated from CALA’s five experimental stations, or “caves,” because ionizing radiation is generated at these locations and requires appropriate shielding.

Laser beams are delivered to the selected cave via a sophisticated evacuated tube system with vacuum chambers and adjustable mirrors. To ensure mirrors are precisely aligned and to prevent accidents during laser handling, CALA required a solution to manage and control all aspects of the facility.

CALA selected MESALOGIC as the system integrator because of their:

As part of the project, MESALOGIC designed an HTML5-based visualization and control solution that integrates seamlessly with the GENESIS64 SCADA platform, giving CALA a powerful, centralized control environment. This interface serves as the foundation for facility-wide management, real-time monitoring, and advanced safety controls, as detailed in the section below.

MESALOGIC also collaborated with HIMA’s Paul Hildebrandt GmbH to design a smart control and safety system for this joint Ludwig Maximilian University (LMU) and Technical University of Munich (TUM) project. HIMA is a global leader in industrial safety solutions, with more than 35,000 TÜV SÜD-certified safety systems installed worldwide.

CALA Control Center, photo credit: MESALOGIC

CALA Control Center, photo credit: MESALOGIC

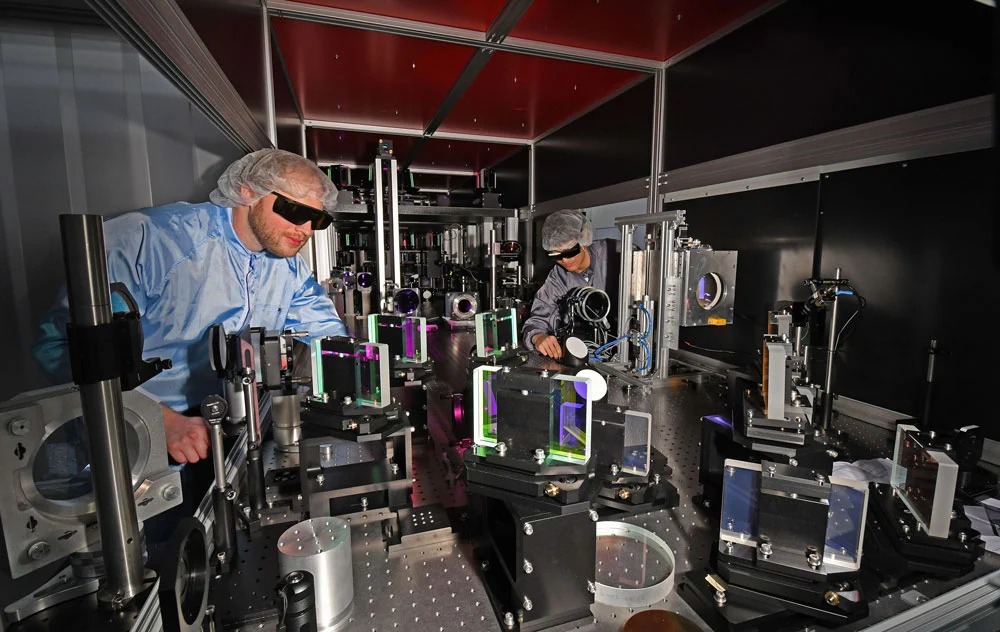

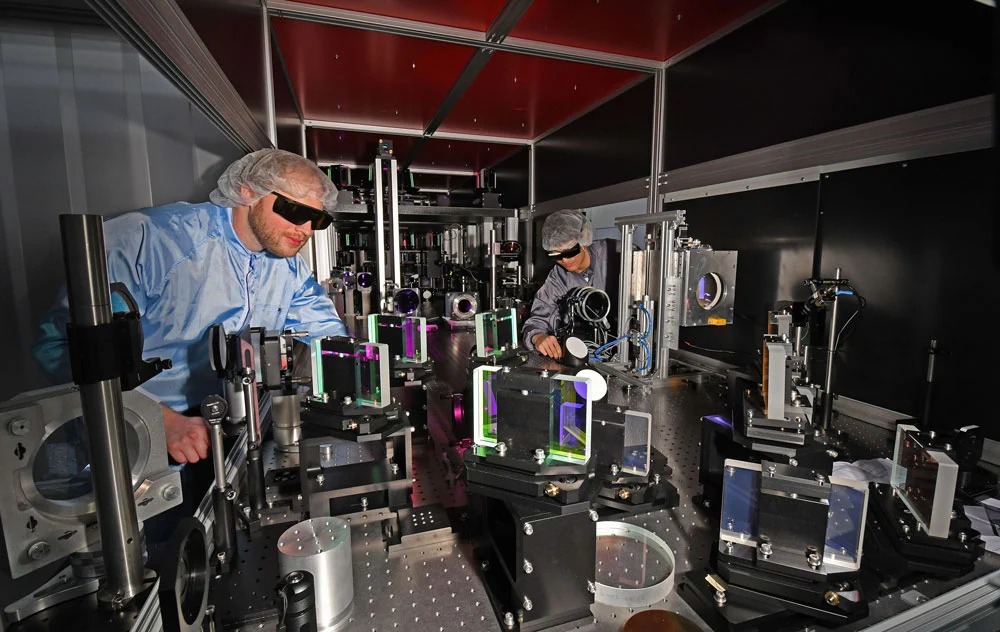

CALA’s ATLAS Laser, Photo Credit: Thorsten Naeser

CALA’s ATLAS Laser, Photo Credit: Thorsten Naeser

CALA’s ATLAS Laser, Photo Credit: Thorsten Naeser

CALA’s ATLAS Laser, Photo Credit: Thorsten Naeser

Caves at CALA, Photo Credit: MESALOGIC

Caves at CALA, Photo Credit: MESALOGIC

The integrated solution from MESALOGIC and Mitsubishi Electric Iconics Digital Solutions delivers a seamless combination of safety, control, and operational efficiency. CALA benefits from:

By combining the robust data logging and configuration power of GENESIS64 with MESALOGIC’s user-friendly HTML5 visualization layer, CALA has achieved a facility-wide control system that is safe, transparent, and built for high-stakes laser research.

Caves at CALA, Photo Credit: MESALOGIC

Caves at CALA, Photo Credit: MESALOGIC

CALA reports that the laser system and test center function as expected and that the researchers are pleased with the reliability and safety the GENESIS platform provides in allowing top-notch laser research to be carried out in a safe and efficient manner.

In addition, MESALOGIC and HIMA were able to rejuvenate the extensive technical infrastructure of the high-tech research facility with advanced process measuring and control safety (MSR) technology and smart control and visualization software