Category: Manufacturing

Dynastar

Sallanches, France

Category: Manufacturing

Sallanches, France

“Dynastar benefits from development from Mitsubishi Electric Iconics Digital Solutions, which resulted in a simple and very powerful solution.”

Since 1963, Dynastar, a division of the Rossignol Group located in Sallanches, France, has designed, manufactured and distributed a wide range of skis and skiing equipment for competition and the general public. Dynastar’s birthplace, Mont-Blanc, provides an incredible laboratory to develop and test tomorrow’s most technically innovative products. Chamonix is Dynastar’s base camp, and its inspiration.

To drive its success, Dynastar works in consultation with athletes, using their valuable feedback to develop new equipment. At the 1992 Winter Olympic Games in Albertville, France, the brand had the highest number of winners, reaching a total tally of three gold, three silver and two bronze medals. Sixty-one years after its creation, Dynastar is one of the world leaders in the ski industry and the brand ranks among the most successful medal winners in history.

“Dynastar benefits from development from Mitsubishi Electric Iconics Digital Solutions, which resulted in a simple and very powerful solution.”

Ski Production at the Dynastar Sallanches, France Plant

Ski Production at the Dynastar Sallanches, France Plant

Dynastar, in coordination with their systems consultant, LANSARD of Pringy, France, selected Mitsubishi Electric Iconics Digital Solutions’ GENESIS64™ HMI/SCADA suite, including AlarmWorX64™ enterprise-wide alarm management system and WebHMI™ Web-based, real-time automation component. They also included GENESIS’ BridgeWorX™ real-time workflow for data bridging and ReportWorX™ real-time reporting/charting/analytics tool.

Ski Production at the Dynastar Sallanches, France Plant

Ski Production at the Dynastar Sallanches, France Plant

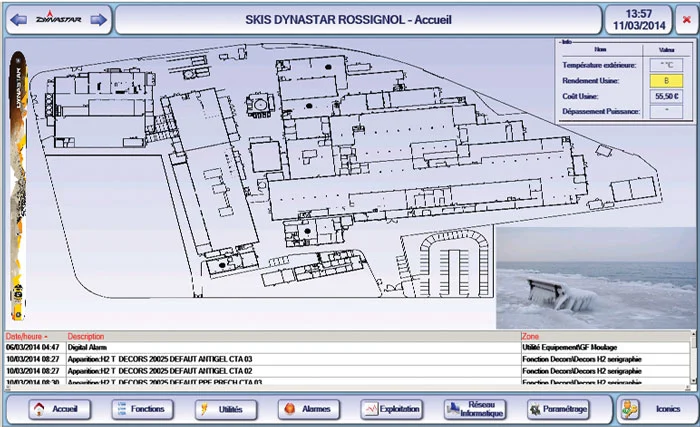

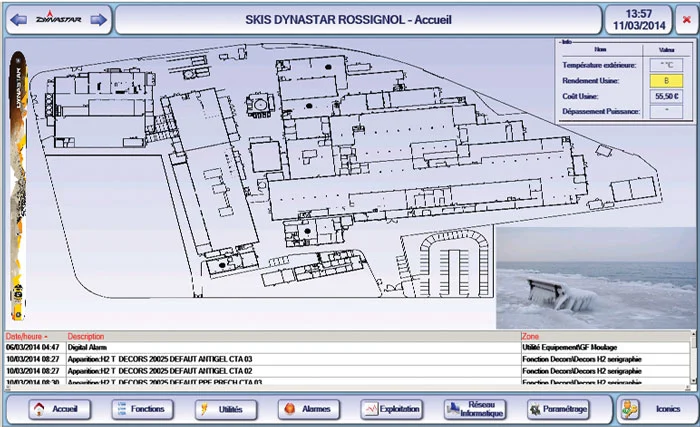

Main screen at Dynastar created with GENESIS64

Main screen at Dynastar created with GENESIS64

Dynastar aimed to update the automation capabilities of its Sallanches location, a 28,000 square-meter facility producing over 300,000 skis per year. Its objectives for this project was to reduce energy consumption related to its manufacturing process, as well as implement a global visualization interface. The company wanted a system that could rationalize the use of production equipment as well as provide warnings of hardware failure. At the time, the company was running Microsoft Windows Server 2008 R2 with multiple Web clients, as well as SQL Server, in addition to Excel, for its database needs. Its existing manufacturing system was comprised of TREND and Honeywell devices, in addition to hundreds of other tags, all of which required an easily integrated automation solution.

The French ski manufacturer required a supervisory product that could allow product managers to set, view and make use of real-time availability requirements of workshops and equipment.

Main screen at Dynastar created with GENESIS64

Main screen at Dynastar created with GENESIS64

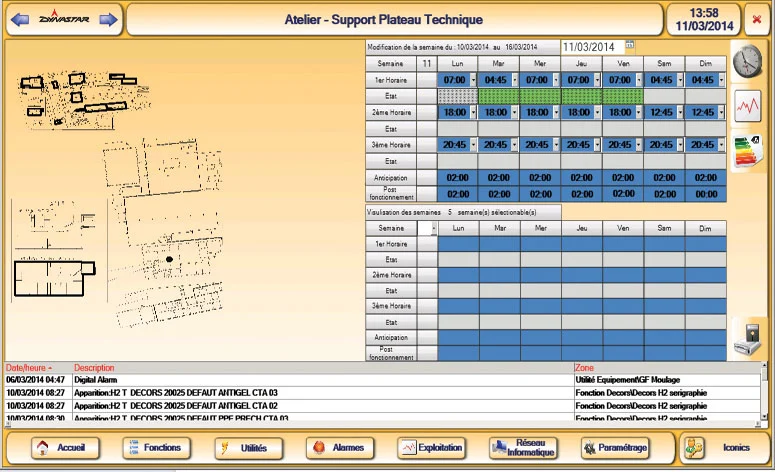

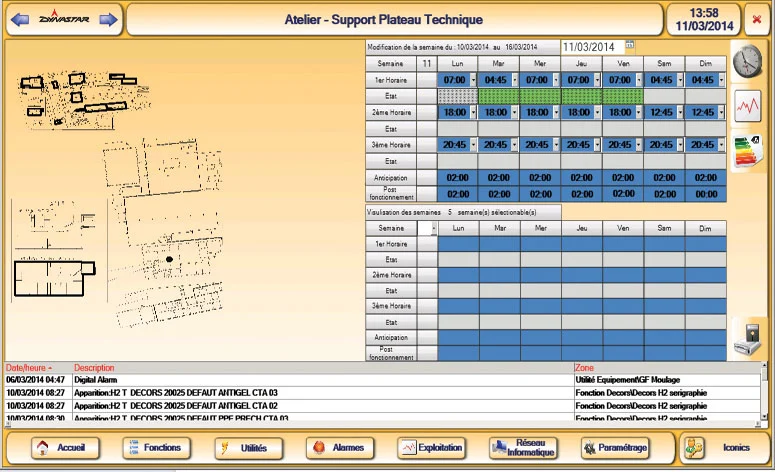

A Dynastar facility management control display

A Dynastar facility management control display

Once Dynastar and LANSARD installed GENESIS64, along with several other Mitsubishi Electric Iconics Digital Solutions software components, the system provided remote access to LANSARD for monitoring and maintenance of Dynastar’s Sallanches facilities. GENESIS is able to handle Dynastar’s large amounts of data — generated from occupation workshops, manufacturing and other sources — and establish an energy consumption profile based on those parameters.

Additionally, the GENESIS solution allows for the connection to, and communication with, multiple different devices over Ethernet via standard OPC and BACnet protocols. Dynastar appreciated its new automation system’s ‘unique’ interface, with Web-based trend dashboards (via TrendWorX64 and GraphWorX64). Additional benefits to the company have been GENESIS64’s ability to perform schedule management, to set user role profiles and to run usage reports, as well as:

A Dynastar facility management control display

A Dynastar facility management control display

Dynastar, with assistance from LANSARD, sought automation software with a simple interface that could integrate with multiple brands of connected equipment. It needed to be a simple, fast and intuitive Web-based solution that would help save the company in energy costs and assist in the scheduling and maintenance of its workshops and manufacturing assets. For other vendors, such requests can cause too many bumps along the way. For Mitsubishi Electric Iconics Digital Solutions, this installation was as straightforward and smooth as Dynastar’s skis.