Category: Manufacturing

PRAKAB a.s.

Prague, Czech Republic

Category: Manufacturing

Prague, Czech Republic

“”

PRAKAB a.s. is one of the largest producers of wires and cables in the Czech Republic, manufacturing power and communication cables as well as building wiring. An extensive investment program was recently launched to modernize the plant and increase production.

Over the last few years, PRAKAB has put new cable production lines into operation, in cooperation with systems integrator, ADAX, Ltd. This was in addition to the reconstruction and maintenance of management systems for existing production lines. ADAX staff was also involved in machine assembly and management systems supply.

“”

Main Control Screen at PRAKAB a.s.

Main Control Screen at PRAKAB a.s.

ADAX, with extensive experience in Mitsubishi Electric Iconics Digital Solutions products, recommended the GENESIS Web-enabled, OPC-integrated HMI/SCADA suite to manage PRAKAB’s production lines.

The deployment includes:

In addition, GENESIS offers recipe capabilities integrated with VBA for flexible process management and reporting tools that store results in Microsoft Excel files and SQL databases.

Main Control Screen at PRAKAB a.s.

Main Control Screen at PRAKAB a.s.

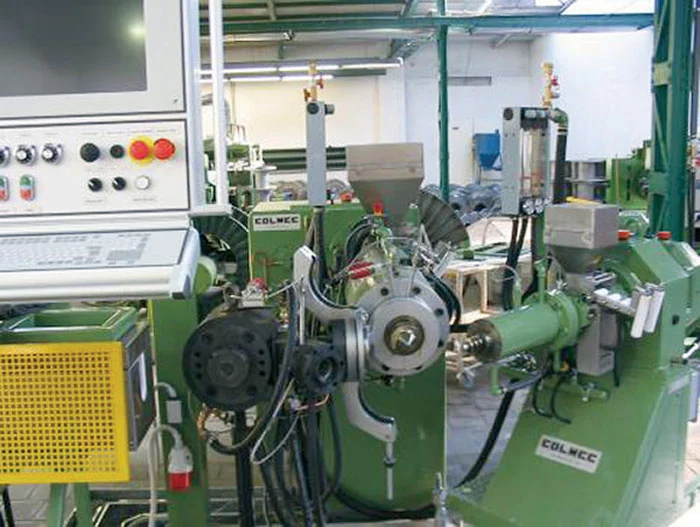

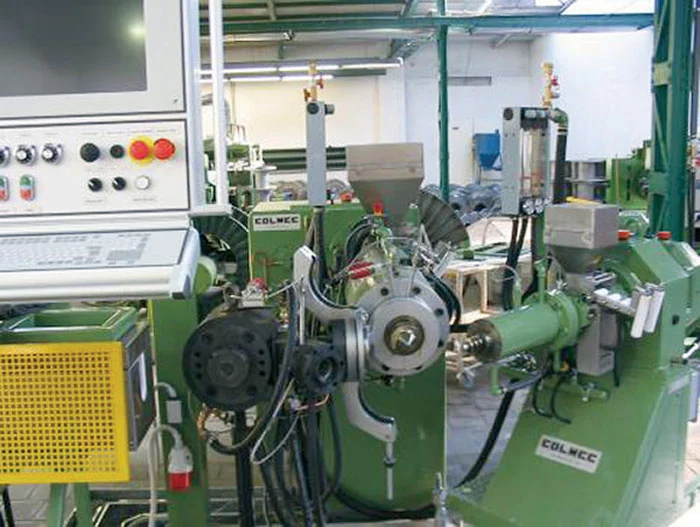

ADAX A Cable Line Extruder

ADAX A Cable Line Extruder

PRAKAB’s manufacturing processes involve multiple machines, including:

An average of 300 I/O points are incorporated into each of PRAKAB’s 15 cable and wire manufacturing lines.

The company primarily uses Siemens S7-300 PLCs, which provide data to the SCADA system over PROFIBUS and Ethernet networks via OPC communication standards.

In addition to Microsoft Excel, SQL Server, and Access database management applications, PRAKAB also runs multiple Microsoft operating systems throughout its enterprise.

ADAX A Cable Line Extruder

ADAX A Cable Line Extruder

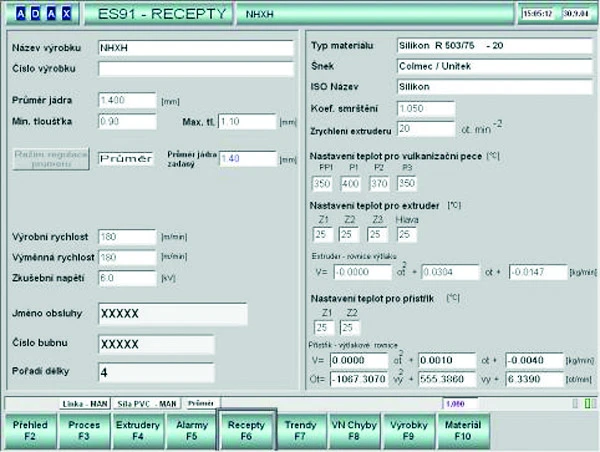

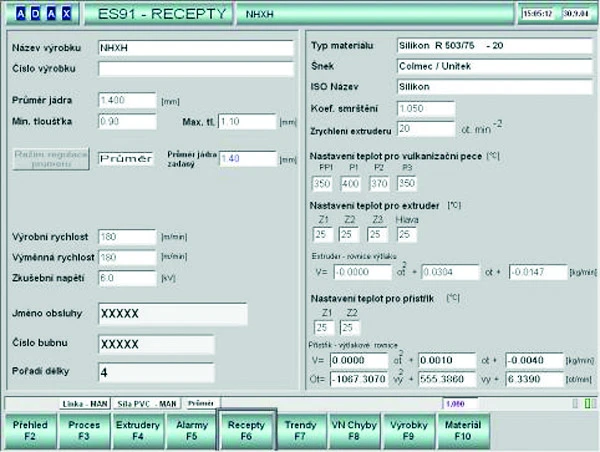

A Recipe Display Screen for PRAKAB a.s. in Prague, Czech Republic

A Recipe Display Screen for PRAKAB a.s. in Prague, Czech Republic

PRAKAB is pleased with the updated system that ADAX provided for the management of its cable production lines. GENESIS HMI/SCADA was selected for its:

These characteristics have significantly shortened implementation time and reduced the total cost of the solution.

The new control system has delivered several measurable benefits:

A Recipe Display Screen for PRAKAB a.s. in Prague, Czech Republic

A Recipe Display Screen for PRAKAB a.s. in Prague, Czech Republic

ADAX has outfitted 12 of PRAKAB’s 15 cable and wire production lines with its updated management and control system, powered by GENESIS—with additional installations planned. Since ADAX recommends the full range of GENESIS industrial automation software, PRAKAB has also mapped out future system upgrades.

Planned enhancements include:

With these initiatives, PRAKAB is taking steps to integrate data from its upgraded production line management system into a comprehensive corporate information system—driving efficiency, visibility, and long-term scalability.