Category: Manufacturing

Vitkovice Steel

Ostrava, Czech Republic

Category: Manufacturing

Ostrava, Czech Republic

“”

Vitkovice Steel, a.s., a member of the Evraz Group S.A., is a leading European manufacturer of rolled steel products. The company’s main product mix consists of plates, sections, sheet piles, and flame-cut shapes. The largest steel plate manufacturer in the Czech Republic, located in the city of Ostrava in the Moravia region, Vitkovice Steel produced 802,000 tons of steel products in 2005, mostly high-quality steel plates

“”

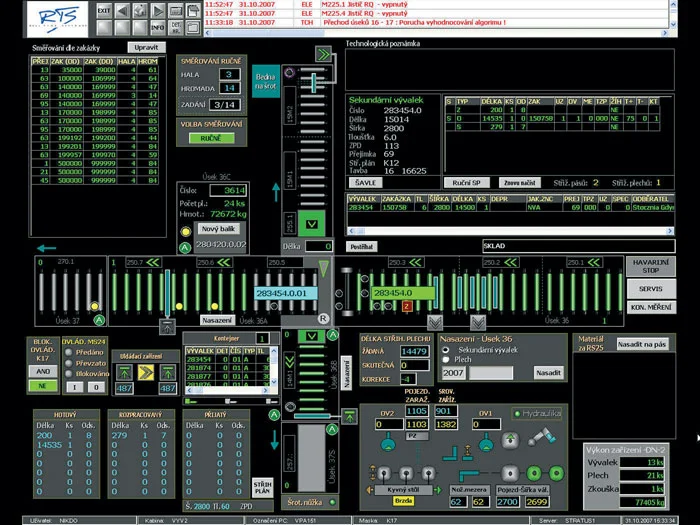

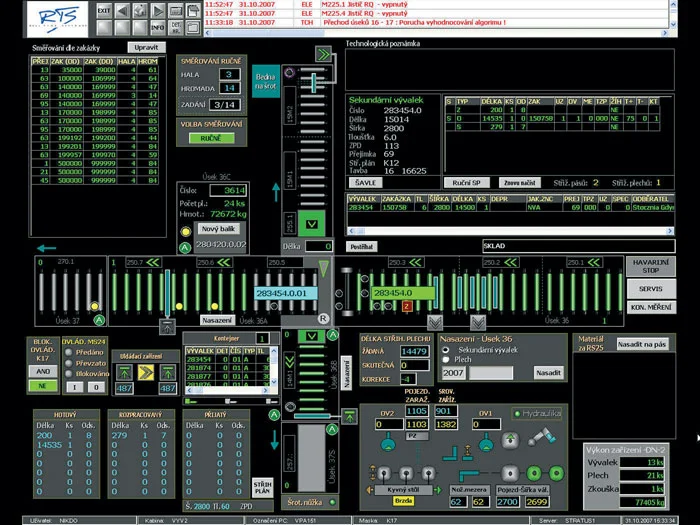

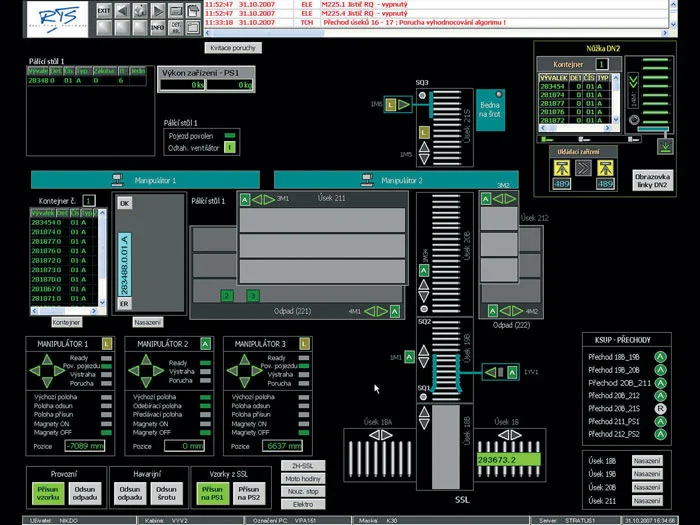

Roll Transporter System Monitor at Vitkovice Steel

Roll Transporter System Monitor at Vitkovice Steel

Vitkovice Steel selected GENESIS™ OPC Web-enabled HMI/SCADA suite, including AlarmWorX™ distributed, enterprise-wide alarm and events management system and DataWorX™ OPC data aggregation, bridging, redundancy and tunneling.

Roll Transporter System Monitor at Vitkovice Steel

Roll Transporter System Monitor at Vitkovice Steel

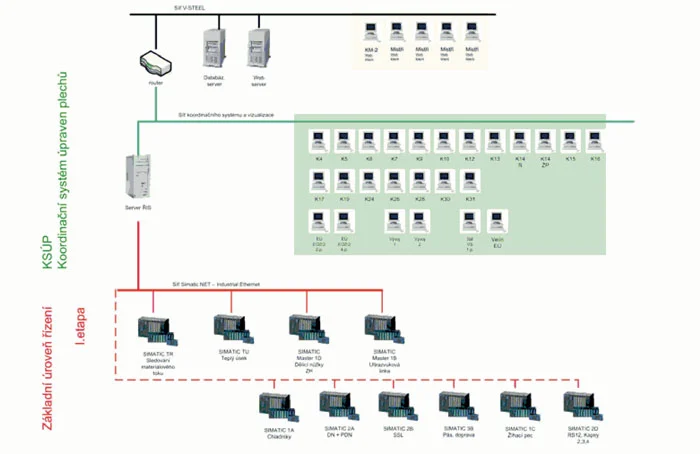

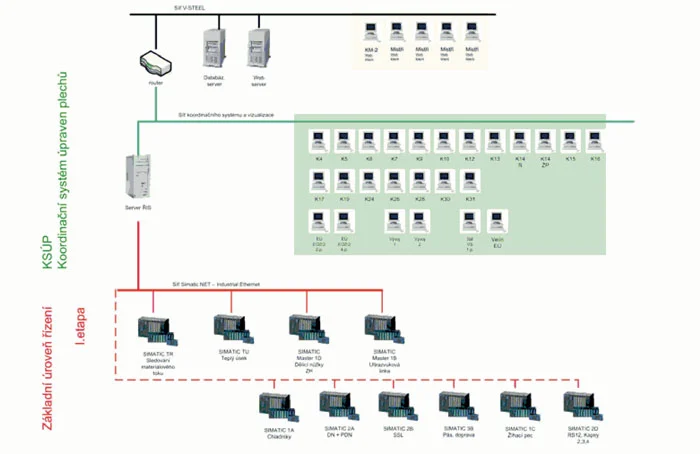

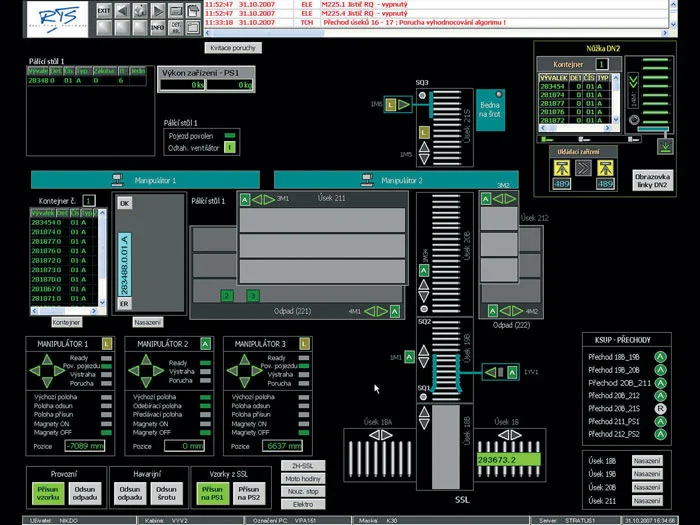

KSUP Systems Overview at Vitkovice Steel

KSUP Systems Overview at Vitkovice Steel

Vitkovice Steel needed to replace a production monitoring system from the late 1980’s, in addition to control systems based on obsolete Czechoslovakian computers (PPC-4). The company, working with systems integrator Real Time Software (R.T.S. c.s., spol. s.r.o.), selected a system based on Mitsubishi Electric Iconics Digital Solutions' GENESIS, integrated with Oracle databases.

The new Plate Mill Coordination System, “KSUP”, was gradually phased in, eventually replacing the former, out-of-date management execution system and the control systems of key production aggregates (units of 3.5 meter, four-high Rolling Mill). The key units contain lengthwise trimming and cutting power slitters/shears, two cross-cutting power shears and roll-transporters.

The GENESIS software suite is used for the automatic monitoring of material moving on roll-transporters as well as of material stored in piles. Operators at service boxes are automatically supplied with all necessary information needed to process the material. The complete production settings are also automatically passed on to the appropriate production aggregates.

GENESIS runs on 26 client stations, providing approximately 40 main operating and overview screens with an additional 250 pop-up window support screens. The diverse user group ranges from general plant and service personnel and guests to developers, administrators and supervisors. The system picks the overall production settings from the superior PPS system. The KSUP system automatically registers all the key parameters of individual production operations and stores them in the Oracle database.

In addition, all alarm and event messages are posted and archived, using AlarmWorX.

KSUP Systems Overview at Vitkovice Steel

KSUP Systems Overview at Vitkovice Steel

The steel manufacturer is pleased by their selection, as it meets their high availability, 24x7 requirements, as well as scales to the needs of about 180 users. With their new GENESIS system, Vitkovice Steel is able to replace older equipment in order to guarantee related maintenance and service. They’re able to respond, with greater flexibility, to user requests in regards to varying production patterns. Integration with existing systems, including KEP Servers, Stratus Servers, Siemens Simatic S7 PLCs, Oracle 9.2 data base, UZ line-over databases, stampers in hot or cold conditions (3964R), and paint stampers is seamless. GENESIS also connects easily to the company’s existing Microsoft products, including Windows Server, Windows and XP clients, Microsoft Office and SQL databases.

Manufacturing Monitoring Screen

Manufacturing Monitoring Screen

When Vitkovice Steel was faced with aging equipment and needed fast, reliable replacement, they immediately considered Mitsubishi Electric Iconics Digital Solutions’ GENESIS. With existing systems to consider, GENESIS was certain to be the right fit, so much so that Vitkovice Steel is considering additional solutions for “fast and easy integration of new production aggregates”.

Manufacturing Monitoring Screen

Manufacturing Monitoring Screen

Vitkovice Steel selected Mitsubishi Electric Iconics Digital Solutions because they meet specific criteria, including: